Professional wood chip machine

| Place of Origin:Henan China (Mainland) | Brand Name:xinyun | color:as requie | certificate:ISO9001:2008 |

| power:37kw |

High efficient wood chips machine

~High efficient wood chips machine simple introduction:

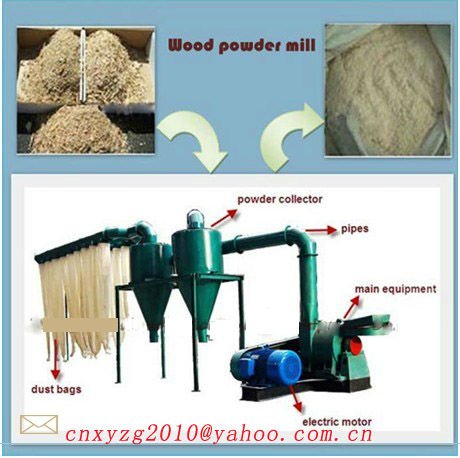

Sawdust machine is a new machine before using the wood powder machine , It can make the wood , wood branches and other raw materials once processed into wood chips, has the advantages of low investment, low energy consumption, high productivity , good economic returns , easy maintenance and so on.

~High efficient wood chips machine usage:

This sawdust machine is especially suitable for wood processing in the Cultivate edible fungus, mainly be made of shavings equipment, crushing equipment and fan machine . Woods that are cut by the crumbs device has Small size, can be sent to the crushing device for a further crushing without drying, crushed wood finished was sent to aggregate locations by fans

~High efficient wood chips machine advantages:

The whole equipment is only need a motor - driven , has the advantages of simple structure , compact layout , and lower prices , stable , low energy consumption , high output , good quality wood finished , low processing costs . It can also be used for cutting the bamboo chips , grass, corn stalks , sorghum stalks, and other fibrous stalk -like materials .

~High efficient wood chips machine Working principle:

It has the double crushing function of blade cutting and high-speed airflow impact, collision crushed , and can complete micro- material sorting processing operations at the same time . In the shredding process of blade cutting , the rotor produce high speed airflow and rotation with blade , the material accelerate in the gas stream , and repeated shock to the material to get the purpose of double crush and accelerate the crush rate.

~High efficient wood chips machine technical parameter:

| Model | SX-800 | SX-600 | SX-400 |

| Dimensions (mm) | 2100×1000×1000 | 2000×800×800 | 2000×800×800 |

| Feeding caliber (mm) | 300×300 | 200×200 | 200×200 |

| The number of rotating blades | 4 | 4 | 4 |

| Sieve aperture (mm) | 2—25 | 2—20 | 2—20 |

| Broken particle size (mm) | ≥0.5 | ≥0.5 | ≥0.5 |

| Motor power(kw | 18.5—22 | 11—15 | 11 |

| Capacity(t/h) | 2—3 | 1—1.5 | 0.8—1 |

| Packaging Detail:standered container or as require |

| Delivery Detail:30 days |