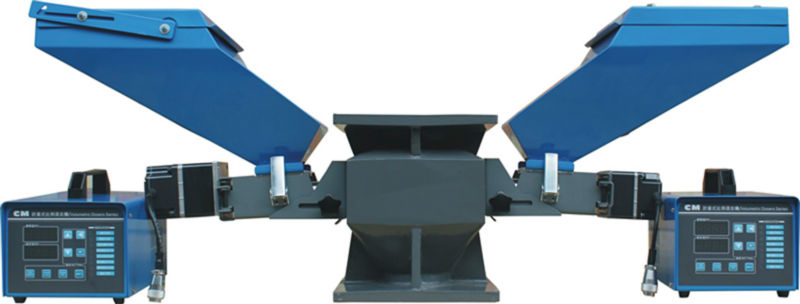

Plastic volumetric doser for injection machine & mixing device & blender for dosing in masterbath & volumetric doser color

| Place of Origin:Guangdong China (Mainland) | Brand Name:Gawell | Model Number:CM-D30/50 | motor (w):50*2 |

| rotate speed of motor:3000 rpm | hopper Capacity:10L*2 | Gear Ratio:30:1/50:1 | Mixer power (W):90W |

| Output Capacity:depended on model that client selecty | Screw External Dia.(mm):up to client's model choice | Dimensions (mm):615*1045*335 | Weight (kg):33 |

CM series volumetric dosers are stuiable for auto-proportional mixing of virgin materials, regrinds, maserbatch or additives. A gear motor with gear ratio of 50:1 or 30:1 is coupled to a dosing screw

of 16,20,25 or 16mm diameter to give a total of six models with output.ranging from 0.1~200kg/hr. Doublecolor dosers can be assembled from two single color dosers if required. Five components automaticmixing can be realized if customers adopt four color dosers.

2.Features

Standard configuration

1)Dosing screws are chrome plated for durability.

2)Unit is comprised of standard modules for ease of cleaning,disassembly and interchangeability.

3)Three-tube magnet is equipped at the base of single colordoser to absorb metal impurieies so to prevent screw ofmoulding machine from damage.

4)Blender is a standard equipment for double color doser tomake the material evenly mixed,while also a optional equipment for single color doser to do so.

5)Main material hopper is a standard equipment for double colordoser. It is optional for single color doser.

6)External single can be directly interfaced with control box.

7)Forced material cleaning is convenient to replace masterbatch.

Features of CM-E

1)Motor rotating speed and plasticizing time can beadjusted simply and directly.

2)High and low potention starts can be selected forIMM connecting singal.

3)Fixed 60-second output testing.

4)Machine halts and sounds alarm when motor faults.

5)Use carbon brush motor,the carbon can be replaceat fixed period.

Accessory option

1) For collocating with GHD-100or GHD-160U and above dryers,havey base should be selected.

2) CM-4 is capable of fulfillingthe adding of four masterbachat most.

3. Working Principle

Signals from control cabinet will be sent to motor. Then itbegins to work. The rotary force is transferred to the dosingscrew through shaft connector. Color additives in hopperwill fall into the groove of conveying screw, then be takento hopper base by rotating action of the screw.

Signals from control cabinet will be sent to motor A/B. Then it begins to work. The rotary force is transferred to the dosing screw through shaft connector. Color additives in hopper A/B will fall into

the groove of conveying screw, then be taken to hopper base by rotating action of the screw and to be mixed by mixing system before sending to moulding machine.

4.Outline Drawings

5.Specifications

Model | Single-color Doser | Two-color Doser | |||||||

| CM30-25 | CM30-20 | CM30-16 | CM50-25 | CM50-20 | CM50-16 | CM-D30/30 | CM-D30/50 | CM-D50/50 | |

| Motor Power (W) | 50 | 50 | 50 | 50 | 50 | 50 | 50×2 | 50×2 | 50×2 |

| Motor Speed (rpm) | 0~3000 | 0~3000 | 0~3000 | 0~3000 | 0~3000 | 0~3000 | 0~3000 | 0~3000 | 0~3000 |

| Output Power of The Mixer (W) | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Screw External Dia. (mm) | 25 | 20 | 16 | 25 | 20 | 16 | * | * | * |

| Output Capacity (kg/h) | 1.1-38 | 0.6-20 | 0.3-10 | 0.5-17 | 0.2- 8 | 0.1- 4 | ** | ** | ** |

| Storage Bin(L) | 10 | 10 | 10 | 10 | 10 | 10 | 10×2 | 10×2 | 10×2 |

| Gear Ratio | 30:1 | 30:1 | 30:1 | 50:1 | 50:1 | 50:1 | 30:1 / 30:1 | 30:1 / 50:1 | 50:1 / 50:1 |

Dimensions | |||||||||

| H mm | 520 | 520 | 520 | 520 | 520 | 520 | 615 | 615 | 615 |

| W mm | 610 | 610 | 610 | 610 | 610 | 610 | 1045 | 1045 | 1045 |

| D mm | 335 | 335 | 335 | 335 | 335 | 335 | 335 | 335 | 335 |

| Weight (kg) | 15 | 15 | 15 | 15 | 15 | 15 | 33 | 33 | 33 |

.

| Packaging Detail:standard export packing. |

| Delivery Detail:7-15 workdays depends on the business |