pet flakes granulation line

| Condition:New | Type:Granulating Production Line | Capacity:100kg/h-500kg/h | Place of Origin:Jiangsu China (Mainland) |

| Brand Name:Lianding | Model Number:pet flakes granulation line | Material:PET | Screw Design:Double |

| Certification:ce | Warranty:one year | After-sales Service Provided:Engineers available to service machinery overseas | equipment material:iron, stainless steel |

| mould:pet flakes granulation line | applicable material:pet flakes | service conditions:380V/3PHASE/50HZ | packing:export standard packing |

| delivery date:30-60days |

PET flakes granulation line

Product Description

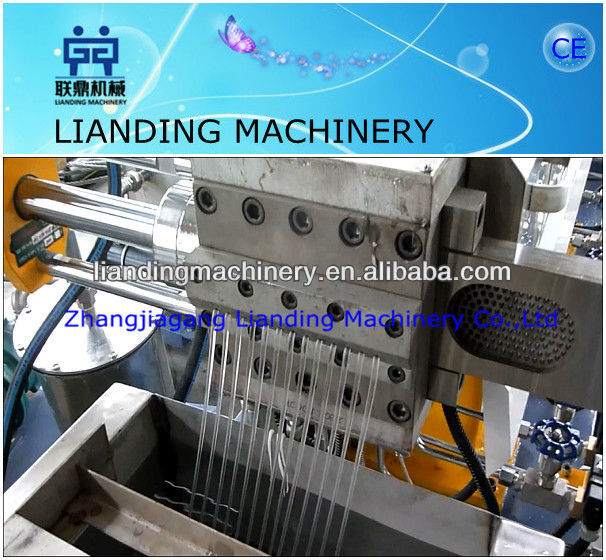

Two-stage extrusion line/plastic extruder line/extruder/plastic recycling and granulation line

Stuctrure:

Stage 1 is single screw extruder

Stage 2 is SJ low speed single screw extruder. Two machines are placed vertically.

Principle and applications:

1. Increasing the operation variables and realizing the process because of two-stage machine

2. High effective and production capacity

3. Good at process heat-sensitive material and devolatilization operation, Such as PVC, XLPE

4. Zero halogen cable, shield material, carbon black etc.

With CE certifications, we have exported to all over world, such as Poland, Germany, Brazil, Holand, etc. With the better after sale service, we are always give our customer the best production line.

1.Co-rotating twin screw extruder

2.L/D:32-64

3.capacity:5-3000kg/h

4.Max. screw speed: 600rpm

5.High-torque and speed

HJ series co-rotating twin screw extruder technical data:

| Parameter Model | Screw diameter (mm) | L/D | Screw rotary speed (r/min) | Motor power (kw) | Capacity/Output (kg/hr) |

| SHJ-20 | 22 | 32-64 | 600 | 4 | 0.5-15 |

| SHJ-25 | 25 | 32-64 | 600 | 5.5/7.5/11 | 5-30 |

| SHJ-30A | 30 | 32-64 | 400/600 | 7.5/11 | 5-40 |

| SHJ-35A | 35.6 | 32-64 | 400/600 | 11/15 | 30-75 |

| SHJ-40A | 41 | 32-64 | 400 | 22 | 65-110 |

| SHJ-40B | 41 | 32-64 | 600/800/1000 | 30/45/55 | 90-275 |

| SHJ-50A | 50.5 | 32-64 | 500 | 45 | 135-225 |

| SHJ-50B | 50.5 | 32-64 | 600/800/1000 | 55/75/90 | 165-450 |

| SHJ-65A | 62.4 | 32-64 | 400/500 | 55/75 | 165-375 |

| SHJ-65B | 62.4 | 32-64 | 600/800/1000 | 90/110/132 | 270-660 |

| SHJ-75A | 71 | 32-64 | 400/500 | 90/110/132 | 270-660 |

| SHJ-75B | 71 | 32-64 | 600/800 | 132/160 | 390-800 |

| SHJ-85A | 81 | 32-64 | 400/500 | 160/200 | 450-650 |

| SHJ-85B | 81 | 32-64 | 600/800 | 200/250 | 550-750 |

| SHJ-95A | 93 | 32-64 | 400/500 | 250 | 750-1400 |

| SHJ-95B | 93 | 32-64 | 600/800 | 315/400 | 945-2000 |

| SHJ-135A | 133 | 32-48 | 400/500 | 550/750 | 1650-3750 |

A Series co-rotating twin screw extruder:Normal Series

B Series co-rotating twin screw extruder:High speed Series

C Series co-rotating twin screw extruder:High torque Series

D Series co-rotating twin screw extruder:High speed and high torque Series

2.Suitable for :

-- Polymer blending & filling modification

-- Engineering polymer & glass fiber reinforcement

-- Masterbatch, functional parent granula, special material ,power coating material

and cable material reactive extrusion , degassing & devolatilization

3.Pelletizing mode:

1) Water cooling strands pelletizing line

(1) High speed mixer (2) Solids conveyer (3)Main feeder (4) Side feeder (5) Glass fiber (6) Twin screw extruder (7) Water trough (8) Air-knife (9) Pelletizer (10) Product container

2) Air-cooling hot face pelletizing line

(1) Metering feeder (2) Twin screw extruder (3) Air-cooling hot face pelletizer (4) cyclone separating device (5) Air-cooling vibrating sieve

3) Water-ring hot face pelletizing line

(1) High speed mixer (2) Main feeder (3) Side feeder (4) Twin screw extruder (5) Water-ring granulator (6) Centrifugal dewatering machine (7) Vibrating sieve (8) Product container

| Packaging Detail:export standard packing |

| Delivery Detail:45 days after receiving the deposit |