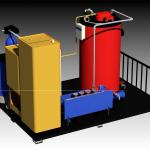

New type Integrated Automatic Series D Biomass Hot water Boiler

| Condition:New | Type:Natural Circulation | Usage:Home/Hotel etc. | Structure:Fire Tube |

| Pressure:Low Pressure | Style:Vertical | Fuel:Wood pellets | Place of Origin:Hainan China (Mainland) |

| Brand Name:AGICO | Model Number:CLHS | Output:Different | Dimension(L*W*H):730X390X1150 |

| Weight:125kg | Certification:CE | After-sales Service Provided:Engineers available to service machinery overseas | Stock:In stock |

| OEM:Can be OEM | Color:Can be made as per buyers' request | Capacity:Variety | Operation guide:Available |

| Price discount:Offered for dealers | After service:Sales after services available | Spare parts:Available | Garantee period:1 year |

1. Structure

This is a five-pass combined detachable biomass boiler consisting of two high temperature furnaces, a secondary furnace, and a built-in heat recovery equipment.

2. Fuel selection

Φ6-8mm slightly coking pellet is applicable.

3. Main features

1) Advanced technology

The two-stage feeding system and the anti-backfire device can prevent backfiring. It combusts with the wind under positive and negative pressure. Electronic ignition function. It installs the fire observation mirror by its side.

Anti-backfire combustion technology make it work even using slightly coking fuel. With the proper operation, the main boiler can be used 5 years with 2 years trouble-free running. The inlet air makes the combustion flame show the white light which can make eyes hurt if we watch it for a certain time. We adopt the special combustion design to compress compulsorily the white light effect. On design of slag-removing, it achieves the automatic slag-removing by pushing the material. The fan controlled by frequency conversion control system, It will not shutdown immediately while the boiler stopped running. Then It runs slowly .It won't stop until the smoke is discharged out of the furnace. It can effectively prevent boiler from explosion which is caused by flue gas. The fan controlled by frequency conversion control system, It reduces the noise.

2) Attractable point

Unique methods of combustion make that series DE boiler can fully fire slightly slagging pellets and slightly coking briquettes and pellets.

3) External storage hopper

Large capacity. Provide the service of customizing large capacity hopper. It runs continuously for 3 to 12 hours by feeding fuel for one time. No need to have a dedicated firemen working on it. The only need is to fill up with the fuel timely.

4) Easy and convenient maintenance

Combined detachable boiler with small size. Easy to clean the ash, convenient to deliver.

Series D | ||||||||

Item | CLHS -0.08 | CLHS -0.12 | CLHS -0.175 | CLHS -0.24 | CLHS -0.35 | CLHS -0.54 | CLHS -0.72 | |

| Rated heating power | 104kcal | 7 | 10 | 15 | 20 | 30 | 45 | 60 |

| Operation pressure | Mpa | Standard pressure | ||||||

| Thermal efficiency | % | 91.15 | ||||||

| Furnace weight | kg | 360 | 375 | 455 | 507 | 797 | 1170 | 1721 |

| Boiler weight | kg | 215 | 255 | 280 | 453 | 625 | 848 | 1175 |

| Fan | KW | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 3 | 4 |

| Fuel consumption | kg/h | 11.34 | 16.2 | 25.7 | 34.2 | 51.3 | 77.5 | 112.4 |

| Smoke-outlet diameter | mm | φ165 | φ165 | φ220 | φ220 | φ220 | φ220 | φ220 |

| Water-outlet diameter | mm | φ57 | φ57 | φ70 | φ70 | φ85 | φ89 | φ102 |

| Heating area | M2 | 500-700 | 700-920 | 920-1400 | 1400-1800 | 1800-2700 | 2700-4500 | 4500-5500 |

| Water capacity | M3 | 0.5973 | 0.697 | 0.956 | 1.243 | 1.758 | 2.239 | 2.521 |

| Water yield | T/h | 1.65 | 2.2 | 3.5 | 4.5 | 6.8 | 10.08 | 13.2 |

| Furnace dimension | Mm | 985×540 ×1200 | 985×590 ×1200 | 1160×640 ×1290 | 1160×690 ×1390 | 1290×790 ×1620 | 1610×890 ×1710 | 1710×990 ×2000 |

| Boiler dimension | Mm | 650×650 ×1200 | 700×700 ×1200 | 800×800 ×1370 | 800×800 ×1520 | 1071×790 ×1620 | 1220×890 ×1710 | 1308×1010 ×2000 |

| Hopper dimension | Mm | 1000×570 ×750 | 1000×570 ×750 | 1000×570 ×750 | 1000×570 ×750 | 1000×570 ×750 | 1100×600 ×750 | 1100×600 ×750 |

| Packaging Detail:Plywood case |

| Delivery Detail:15 days |