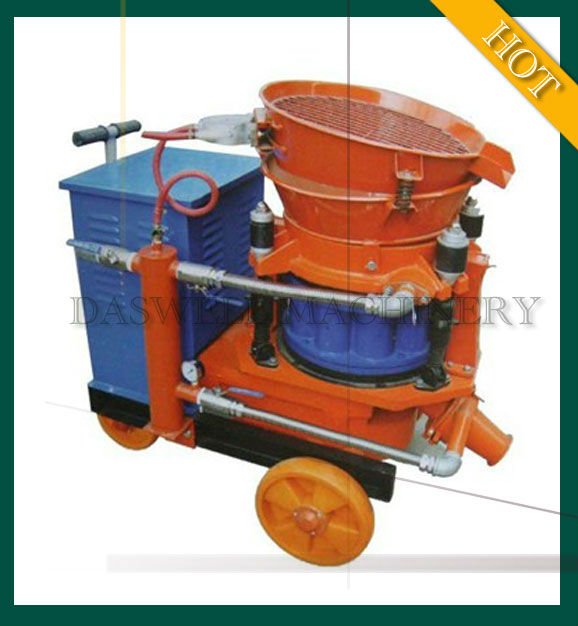

most popular durable PZ-3 dry shotcrete machine

| Condition:New | Place of Origin:Henan China (Mainland) | Brand Name:DASWELL | Model Number:PZ-3 |

most popular durable PZ-3 dry shotcrete machine

Introductions of PZ Series Shotcrete Machine:

Shotcrete process is to use compressed air to convey the pre-dampened mix through delivery hose to the nozzle to project the material onto the sprayed surface under high velocity, and then to form concrete support layer after the projected material coagulates and hardens. With simple technology, special effect, economy cost, flexibility and high construction efficiency, shotcrete technology has widely been applying in construction, railway and super highway engineering, underground engineering, tunneling, mining operations, hydropower projects and slope stabilization, etc. and showing prosperous future.

Advantages of PZ series shotcrete machine:

1. Non-adhesion going-through rotor with new material chamber, completely eliminate bonding and blocking during operation so as to reduce clearance and maintenance period.

2. Thin flow conveying method with vortex flow, so the spraying flow is even, continuous and steady, to improve the shotcrete quality.

3. Four-point clamping device make it easy to adjust the press between sealing plate and rotor disk so as to no air and dusk leak and prolong consumption parts life.

4. This is a high-effective shotcrete machine,which is mainly used for dry-mix, damp-mix shotcreting and steel fiber reinforced shotcreting.

5. Four-point clamping device make it easy to adjust the press between sealing plate and rotor disk so as to no air and dust leak and prolong consumption parts life.

Applications of PZ series shotcrete machine:

1. PZ series Gunite machine is a kind of Shotcrete machine fortunnels,hydro-power engineering,mines,underground engineering, civil engineering and slopestabilization,etc.

2.Refractory material sprayingand repair for industrial kilns or kilns's inner liner.

Technical Parameters of PZ series shotcrete machine:

| Type | PZ-3 | PZ-5 | PZ-9 |

| Name | |||

| output | 3 /h | 5.5 /h | 9 /h |

| Max conv. dist | 200 m | 200 m | 150 m |

| Water cement ratio | < 0.4 | < 0.4 | < 0.35 |

| Max Aggregate size | 10 mm | 15 mm | 20 mm |

| Hose inner size | φ42/50 mm | φ50 mm | φ64 mm |

| Operating air pressure | 0.2-0.6 MPa | 0.2-0.6 MPa | 0.2-0.6 MPa |

| Air consumption | 5-6 /min | 7-8 /min | 9-10 /min |

| Motor power | 3 kW(4hp) | 5.5 kW(7.5hp) | 7.5 kW(10hp) |

| Voltages | 380V,440V,660V,1140V 50Hz/60Hz | ||

| Basic chassis | Basic chassis is tyre 1.Skid 2. and rail-wheel 3.are optional | ||

| Packaging Detail:Standard export package |

| Delivery Detail:15~20 working days after receiving down payment |