mining use belt conveyor training idler roller

1.Dustproof&Waterproof., 2.Low Friction Coefficient., 3.Longlife:more than 35,000hours. - details see: https://www.machineto.com/mining-use-belt-conveyor-training-idler-roller-10202233

| Place of Origin:Shandong China (Mainland) | Brand Name:Wuzhou | Model Number:carrying idler | parts for conveyor:Idler for belt conveyor |

| mine haulage:bearing | | | |

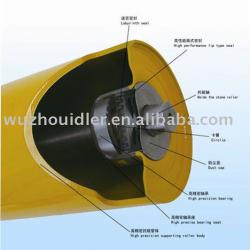

Roller inner structure and material:

(a) Shaft: Bright drawn steel to required bearing tolerance

(b) Shaft end: Both ends of tube are simultaneously machined and chamfered

(c) Bearing: Single and double row deep groove ball bearing 2RZ and 2Z with C3 clearance

(d) Seals: Grease retaining inner seal with multi-stage labyrinth and retention cap with outboard rubbing flinger seal

(e) Lubrication: Grease is lithium soap type grease with rust inhibitors

(f) Welding: Mixed gas shielded arc welding end

(g) Our roller saves on repair and maintenance costs of the conveyor belt due to the concentric design which decreases vibration

Advantage:

(1)Low friction coefficient, warterpoof, effective sealing system,

(2). High accurate steel pipes ensure the rollers with low vibration and noise.

(3) Multi-labyrinth seals achieve waterproof and dust proof.

(4). Adopt good bearing make sure the long lifetime, stable running and good quality.

(5). Stable running, good quality and attractive price.

4. The specification range that we can provide:

Diameter: 50 to 219mm

Length: 190 to 3, 500mm

we can produce according to the customers requirement.

| Packaging Detail:wooden case |

| Delivery Detail:within 30 days |

Related Product for mining use belt conveyor training idler roller