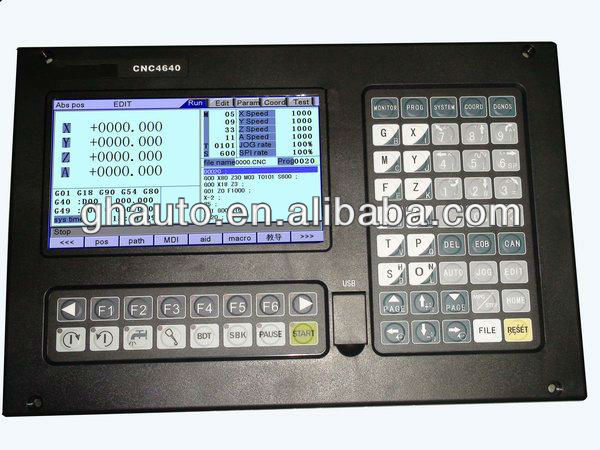

Milling CNC System

| Place of Origin:Guangdong China (Mainland) | Model Number:CNC4640 | Condition:New | After-sales Service Provided:Overseas service center available |

The Milling CNC System is professional applied to all kinds of CNCDrilling &Milling machine. Presently, CNC4640 is very popular model and has stable performances and many functions, matched with our AC servo drive unit to compose the high performance and suitable CNC solution. The system can match other drive units according to the user's requirements.

Feature:

1) 7.0 Inch TFT color display, 800 X 400 high resolution .

2) U flash and USB communication port, USB TO PC communication connector.

3) Multi-language

4) Support macro command programming in sentence type

5) ARM 9 CPU+FPGA double core processor

6) PLC function (developing)

7) Four channel 2 mb/s high speed pulse output , 6 channel AB phase decoder

8) Two channel serial RS232 connector.

9) SD card big capacity memory connector.

10) Support 4 axis linkage.

11) One channel for handheld box, supporting external MPG

12) Ethernet network interface, 10/100M Ethernet port.

Technical specification

1) 4 axes(X, Z, Y, A),and 7.0″large screen LCD, 800X480

2) Display in Chinese, English and etc,.

3) Interpolation axes: X, Y, Z, A axis

Maximum any 4 axes linear continuous interpolation

IF use manual programming(G code). support maximum any 2 axes circular(spiral) continuous interpolation.

IF use software programming (e.g. UG.MACH3.PRO/E).support maximum 4 axes linear and spiral(circular) interpolation

4) Support mircosoft-program.it is similar to PLC. Can do a lot of logic control and axes control

5) Feeding axis function

6) Support pitch error compensation and backlash compensation

7) Minimum command unit: 0.001mm can be selected

8) Position command range: ±9999× minimum command unit

9) Maximum rapid traverse speed is 20m/min when command unit is 0.001mm. rapid traverse frequency 500K. interpolation frequency 200K

10) Be able to adjustment from F0-150%,total 15 levels, real time

Rapid traverse and feeding are use the same switch

11)Auto chamfering

12) Acceleration and deceleration function

Cutting feeding: Acceleration or deceleration in linear type/index type or front/rear is selectable.

Rapid traverse: Acceleration or deceleration in linear type/index type or front/rear is selectable.

Use linear type acceleration and deceleration, and support the symmetrical

Tapping: Acceleration or deceleration in linear type/index type or front/rear is selectable.

The starting speed, finishing speed and time of acceleration and deceleration are set by the parameter.

Spindle function :

Analog voltage 0V~10V output, support spindle control

Transmission ratio between encoder and spindle is:(1~255)

Spindle speed: It is specified by S code ,the speed range is 0rpm~9999rpm.

Spindle override: total 0-150% 15 levels, real-time adjustment

Spindle constant surface speed control

Tapping cycle/rigid tapping

13) Support tool function : such as:

Tool length compensation

Tool radius compensation

Tool life management

14) Precision backlash compensation and pitch error compensation in memory type .

15) Operation management

Operation mode: Edit, auto, MDI, machine zero-return, MPG/single step, manual and DNC.

Operation authority of multiple levels management and alarm record

16)Editing program:

Program capacity: 40M, 10,000 programs (including subprograms, macro programs)

Editing function: program/block/characters research, rewrite and delete

Program format: ISO code, support macro command programming in sentence type

Calling program: It supports macro program with parameter, subprogram nesting of 4 layers

17) RS232andUSBcommunication function:

RS232: Files of part program and parameter, etc can be transmitted in two-way, DNC real-time processing, serial ports of system software upgrade.

USB: File operation, directly processing files, system software upgrade in flash disc.

18)Support Safety function, as following:

Emergency stop

Hardware travel limit

Software travel limit

Data restoring and recovering

Optional Spare Parts:

| Packaging Detail:with carton, every package for 1 pcs , as standard package of SZGH size: 42*32*27weight: 6.5KG |

| Delivery Detail:3-5days |