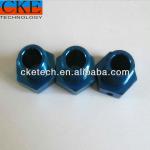

Metal injection moulding

| Place of Origin:Shandong China (Mainland) | Brand Name:WTD | Model Number:OEM | Type:MIM |

| Material:Stainless steel | Technology:Metal injection molding,MIM |

Metal injection moulding,Metal injection molding,MIM parts

Metal Injection molding (MIM) is a metal processing technology that converts metallic powder into useful engineering components of various shapes and properties. The major advantage of MIM is its ability to make highly complex, high precision parts at a fraction of the cost of competing technologies such as machining and investment casting. It has gained widespread popularity in a wide array of applications from automotive seat belt components, electric contacts, soft magnetic cores, to a variety of structural applications.

Benefits of the MIM Process:

Excellent Surface Finishes

Ability to use the benefits of

Controlled Porosity

Excellent Tolerance Control

Very Good Net-Shape Capabilities

Low to High Volume Capable Process

Very Cost-Effective Processing

Inexpensive Materials

Over the past 20 years, Wontide has become an industry leader in conventional press and sintered materials. We specialize in complex, multi-level components; with materials offerings range from stainless steel,iron based material,iron-nickle alloy,tungsten carbide etc. We provide MIM solutions to industries from automotive, medical,electronic...

| Packaging Detail:in cartons |

| Delivery Detail:25 days |