machine for chemical fiber and wool maxiao@qdclj.com

| Place of Origin:Shandong China (Mainland) | Brand Name:Chenglijia | Model Number:FN271F | Machine width:1200mm;1500mm |

| Applicable materials:the length 25~127mm,the fineness 0.8~30D | Delivery tops weight:7~20g/m | Total draft multiple:32~140 | Max.delivery speed:200m/min |

| Max.productive capacity:240kg/h per set | Cylinder working dameter:770mm | Cylinder speed:400rpm(frequency control) | Air consumption for dust suction:2200m³/h per set |

| Total power:12kw | Machine Type:Carding Machine | Material Capabilities:Fiber | Product:Cotton sliver |

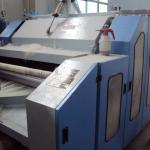

FN271F high production carding machine

PRODUCT USAGE:

This machine is applicable to open, card and blend chemical fibers and mixed fibers, condense them into wool tops of certain specifications, and then coil them into sliver can regularly for the following process.

MAIN TECHNICAL SPECIFICATION

| Machine width | 1200mm; 1500mm |

| Applicable materials | the length 25~127mm and the fineness 0.8~30D |

| Feeding form | Double-box volumetric type automatic continuous feeding with photoelectric control |

| Delivery tops weight | 7~20g/m |

| Total draft multiple | 32~140 |

| Max.delivery speed | 200m/min |

| Max.productive capacity | 240kg/h per set |

| Cylinder working diameter | 770mm |

| Cylinder speed | 400rpm(frequency control) |

| Licker-in working diameter | 250mm |

| Licker-in speed | 600rpm(frequency control) |

| Doffer working diameter | 650mm |

| Doffer speed | 10~75rpm(frequency control). |

| Air consumption for dust suction(continuous) | 220m³/h per set |

| Coiler type | Manual type,3-position or 4-position automatic can changer |

| Applicable sliver can specification | Φ600mm×900mm,Φ400mm×1100mm(optional) |

| Total power | 12kw |

| Floor space(L×W) | (width 1.2m)11000×2290,(width 1.5m)11000×2590 |

| Machine weight | 11000kg |

MAIN FEATURES:

1.The feeding part is equipped withmetallic and hard matters detecting deviceandover-thick layers stop motionto guarantee the safety of the machine.

2.The licker-in is equipped withover-low speed stop motionin order to prevent the machine jams.

3.The machine is equipped withbroken tops stop motion.

4. The machine is equipped withsuction systemfor collecting flyings and short fibers on the machine so as to prevent machine jams and reduce the cleaning frequency.

5. The input layers areadjusted automatically by the autoleveller system, so as to guarantee the evenness and stability of wool tops.

6.The coiler with 3-working position or 4-working position auto changer can further lessen the labor intensity of workers.

7.The electrical control box is located inside the framework of the front part of this machine; thetouch display screenis fixed on the left encloser of the front part of the machine, so it's convenient to operate and the working space is increased.

8. In the automation control, this machine realized the communication between the PLC and the touch screen; with the touch screen to set and amend the technological parameters and observe the working conditions of all the running parts and the faults in time, and with the Man-machine conversation PLC to control the inverter and make the frequency more stable, so as to guarantee the machine's normal running.

9.Adopt totally-enclosed safety cover, with good appearance and in perfect order.

| Packaging Detail:to be packed in seaworthy strong wooden case or carton |

| Delivery Detail:within 20 days after the receipt of down payment |