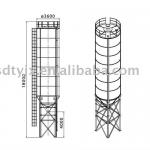

Low cost grain storage steel silo 50t for poultry house

| Condition:New | Capacity:68m3,50t | Material:Steel | Place of Origin:Shandong China (Mainland) |

| Brand Name:TSE | Model Number:TCZK03605 | Model:TCZK03605 | Diameter:3.668m |

| Layer:5 rings | Volume:68m3 | Ring beam height:2.690m | Eave height:8.345m |

| Total height:9.190m | Roof angle:25 degree | Bottom angle:45 degree |

Grain storage steel silo silo made of 275g/m2

Shelley Engineering Co., Ltd. is a company professionally produce and sell grain storage silos.

As the main supplier of steel farms and commercial storage bins and silos in China, we offer the most technologically advanced grain dryers in the industry and a large selection of material handling systems, including sweep augers, drying and cleaning systems, commercial bucket elevators and conveyors.

Main Features: It is popular with its simple structure, large capacity, various ways of unloading. Further more flat bottom steel silos can be easily maintained.

Flat bottomed steel silos are with large diameter and capacity, which is popular for its easy installation and lower costs. There are many ways for unloading, such as the free-fluidized unloading, multi-spot unloading, the flat bottom sweeping unloading and clean by hands etc... We can also choose the concrete conical bottom to put the automatic-flow unloading into practice. The flat-bottom steel silos can be widely used in grain process and storage lines, some of them can be chosen to be used in oil, feed, flour, starch, brew, and port or grain storage industrial lines.

Performance and Character:

Our bolted steel silo is used to store grain, seed, feed, cement, coal and other granular or powdered materials. Popular uses for our product include, Temporary Transit, Raw Material, and Grain warehouses. Current applications of the Bolted Steel Silo is to provide efficient and affordable storage solutions for grain warehousing, alcohol plant, flourmill, oil mill, starch factory, feed mill, malt factory, distilleries, seaport, farm, and grain-processing centers, etc.

Some advantages of our product:

1. Lower basic cost with lightweight, low request for foundation, low consumption of steel.

2. High degree of standardization. We can produce the standard components which can be installed on-the-spot.

3. Simple, easy and efficient to install within a short amount of time due to superior component design which are connected by standard bolts.

4. Easy to understand. The bolted silo is equipped with relevant accessories, such as: conveyor, ventilation, drying and monitoring devices, etc. to ensure the quality and safety of the material stored in the silo.

5. Easy to maintain. As the parts of the silo are connected by standard bolts, so it is easy to remove or repair it.

6. Low cost and long tenure of use. The cost of bolted silo is just 35%-50% of the cement silo with the same specification; and its life span can reach 30 years.

Structural Outline

The structure consists of two parts: The body and the roof.

1. The Silo Body

Include the wall plate, column, manhole, roof ladders and so on.

(1) The wall plate

Our steel is hot galvanized, which makes it durable and weather resistant. Our advanced bolts with spherical washer and the resisting-worn rubber are used to ensure the tightness and using period.

(2) Column

The column, made by the Z-bar, is used to reinforce the silo body. It is connected by junction panels.

(3) Manhole and Roof Ladders

There are inspection door and ladders inside and outside the silo body. It is convenient and accessible for any maintenance work.

2. Roof

Roof is made up of radiated beam, roof cover board, tension ring, ventilator scoop, roof cap, etc.

The space age construction technology, which is adopted in the design of the silo framework, can ensure the stability of silo under the large span.

There is a guardrail around the silo eaves and there is also a manhole on top of the roof.

Specification:

Commendatory letter

SILO PROJECT

WELCOME TO VISIT US!!

| Packaging Detail:no packing |

| Delivery Detail:within 25 days |