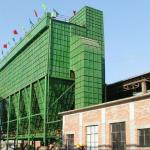

latest high quality pulse bag dust filter with ISO CE approved

| Condition:New | Type:ESP Dust Collector | Place of Origin:Henan China (Mainland) | Brand Name:Hongji |

| Model Number:DMC series | Dimension(L*W*H):depends on the model | Certification:ISO CE SGS | Warranty:one year |

| After-sales Service Provided:Engineers available to service machinery overseas | Color:Different color as client required | Wind capacity(m³/h):1500-21600 | Wind filtration speed(m/min):1-4 |

| Running resistance(Pa):≤1200 | Air consumption(m³/min):1.5-7.5 | Blower power(kw):2.2-11 | Pressure(Mpa):0.4-0.6 |

| Installation:Under our engineer's guide | Spare parts:Supply by us | Product name:pulse bag dust filter |

latest high quality pulse bag dust filter with ISO CE approved

1. Company Introduction:

Our factory is a manufacturer and exporter of mining machinery in China.

Our main products aregrinding mill, briquetting machine,sand making production line, stone production line, magnetic separating production line, Flotation separating production line, cement production line, crusher, dryer, rotary dryer, rotary kiln, coal gasifier, conveyor, ball milland so on.

All of them are ISO9001:2008 confirmed.

2.Description of pulse bag dust filter:

DMC Pulse Dust filter is a kind of highly efficient filter which is designed on the base of overseas advanced technology. It combines advantage of locellus blowback dust collector and jetting pulse cleaning dust collector, avoids less strength of locellus blowback and simultaneous re-absorbing of jetting pulse cleaning dust and filter. It adopts highly efficient off-line method, so it can clean dust with larger capacity, higher efficiency, lower system resistance, longer life of filter-bag, etc.

3. Pulse bag dust filter application:

It is widely used to collect dust in grinder, crusher, packing machine, silo top, matching materials of cement industry. It can clean not only air with common dust, but air withhigh density (even 1300g/Nm³), so it can collect final product of vertical mill and 0-sepa separator. It can be also widely used in grain, light industry, electric power, chemical industry, metallurgy, etc.

4.Pulse bag dust filter:

1. Off-line method cleans dust and dust collecting efficiency can reach 99.99%, there is no second dust absorbing, so it is suitable to deal with smoke with high density, and can directly collect product with high density.

2. Filter material with high quality can meet any working condition.

3. PLC intelligent controlling system can be operated easily, precisely and reliably.

4. Gas tank structure and module manufacturing make installation much easier.

5. Advanced balancing wind design reduces operating resistance of dust collector.

5.Working Principle of pulse bag dust filter:

1. The dust-laden air enters the bag filter.

2. The dust /powder separates inside the bag filter chamber.

3. The air is uniformly distributed avoiding channeling while the powder is separated.

4. Initially a coat of material forms on the bags. Subsequently,the coat acts as the filtering medium.

5. The dust is accumulated on filter elements while the air passes through the filter bags from outside to inside.

6. The accumulated powder is dislodged from the bags by reverse pulsejet air intermittently.

7. The dislodged powder falls on bottom cone and is discharged through powder discharge valves.

8. The dust free air is sucked by induced draft fan and is exhausted to atmosphere.

6. Export country of pulse bag dust filter:

Russia,India, Vietnam, Kazakhstan, Mongolia, Pakistan, Iran, Ecuador, middle east, Oceania, Europe , America and other countries and areas.

7.Technical parameters:

| TYPE | Wind capacity (m3/h) | Wind filtration speed (m/min) | Filtration area (m2) | Bag number (strip) | Pressure (Pa) | Thickness (g/m3) | Thermal insulation layer area (m2) | Weight (kg) |

| 32-3 | 6900 | 1.2-2.0 | 93 | 96 | 1470-1770 | 1000 | 26.5 | 2.880 |

| 32-4 | 8930 | 124 | 128 | 34 | 4.080 | |||

| 32-5 | 11160 | 155 | 160 | 41 | 5.280 | |||

| 32-6 | 13390 | 186 | 192 | 48.5 | 6.480 | |||

| 64-4 | 17800 | 248 | 256 | 70 | 7.280 | |||

| 64-5 | 22300 | 310 | 320 | 94 | 9.960 | |||

| 64-6 | 26700 | 372 | 384 | 118 | 11.640 | |||

| 64-7 | 31200 | 434 | 448 | 142 | 13.320 | |||

| 64-8 | 35700 | 496 | 512 | 166 | 15.000 | |||

| 96-4 | 26800 | 372 | 384 | 1300 | 110 | 10452 | ||

| 96-5 | 33400 | 465 | 480 | 120 | 12120 | |||

| 96-6 | 40100 | 557 | 576 | 130 | 14880 | |||

| 96-7 | 46800 | 650 | 672 | 140 | 16920 | |||

| 96-8 | 53510 | 744 | 768 | 150 | 19810 | |||

| 96-9 | 60100 | 836 | 864 | 160 | 21240 | |||

| 96-2×5 | 66900 | 929 | 960 | 175 | 25200 | |||

| 96-2×6 | 80700 | 1121 | 1152 | 210 | 30240 | |||

| 96-2×7 | 94100 | 1308 | 1344 | 245 | 35280 | |||

| 96-2×8 | 107600 | 1494 | 1536 | 280 | 40320 | |||

| 96-2×9 | 121000 | 1681 | 1728 | 315 | 45360 | |||

| 96-2×10 | 134500 | 1868 | 1920 | 350 | 50400 |

| Packaging Detail:export standard or nude packing,spare parts in wooden case or according to customer's demand |

| Delivery Detail:in 10-25 working days after confirm the order |