K400 monel wire mesh (manufacturer)

| Place of Origin:Hebei China (Mainland) | Brand Name:bolin | Model Number:bolin | Usage:Liquid Filter |

| Type:galvanized wire mesh | Material:Metal Fiber | Hole Shape:Round | Filter Rating:95% |

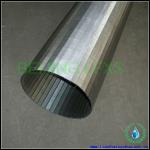

| Thickness:1.5cm | Length:1m | Width:30m | material :monel wire:type :weave |

| wire dia:0.1-2.5mm:mesh:20-200 | width:1-2.5m:length:15-30m |

K400 monel wire mesh

Monel K400wire mesh is the high corrision resistance.The main chemical cormposttion is Ni 65%,Cu 30% and little part of Fe(1%-2%).Mainly used in chemical and oil.

Monel K500has more strength and hardness than Monel K400.This because add Al Ti into it.Monel K500 has the same corrision resistance as Monel K400.Monel K500 is sutiable in usding sea water.

weave: plain weave and twilled weave.

description: acid resistance and high temperature

With the way: used for acetic acid, vinegar liver and other acids environment conditions screening and filtering, power plant high temperature, oxygen mesh screen.

Mesh/inch: 30 - -200 mesh

| Nickel - Nickel is widely used in woven wire cloth as a corrosion resistant medium. It protects itself by forming a passive oxide film, thus resisting corrosion in many oxidizing environments. In today's industry, nickel is replaced with stainless steel when Possible for cost savings. Monel - This alloy is essentially non-corrodible. Composed of 67% nickel, 28% copper and 5% others. Monel is more corrosion resistant than copper in oxidizing conditions and more resistant than nickel under reducing conditions. Monel has good strength characteristics and has traditionally been used in food processing. As with nickel, it can be replaced with stainless steel. Hastelloy B - This alloy is used for corrosion resistance to hydrochloric acid in most concentrations and at temperatures up to the boiling point. It is not recommended for high temperature service. Hastelloy C-276 - This alloy is well suited to corrosion resistance service against strong oxidizing agents such as ferric chloride and cupric chloride. Good elevated temperature properties in the 1600 to 1800 range Carpenter 20 Cb-3 - A corrosion resistant alloy especially useful against hot sulfuric acid. Not normally used for high temperature service. Incoloy Alloy 800 - The nickel and chromium content here are similiar to Carpenter 20 Cb-3, while the copper and molybdenum content are reduced. Used in high temperature and corrosive environments. Inconel Alloy 600 - 72% nickel and 15% chromium content makes Inconel 600 suitable for high temperature applications where corrosion resistance is important. Frequently used for heat-treating baskets. : Nichrome - A 60% nickel and 15% chromium alloy used in certain chemical conditions at temperatures up to 1700 Contains 1% silicon which helps keep scaling to a minimum. Subject to carbide precipitating characteristics. Nichrome V - Similar to Nichrome, this alloy has a higher nickel content - 80% nickel and 20% chromium. It is used in severe chemical conditions at elevated temperatures up to 2000 |

FeCrAlY (commonly referred to as Hoskins 875 ® Hoskins Mfg Corp)C .03% Cr 21-24% Al 5-6% Mn .50% Si .2-1% S .005% P .03% Y .01% B .005% Fe balance

FeCrAlY is a heat resisting alloy with excellent oxidation resistant characteristics. The addition of Yttrium inhibits scaling. This alloy has a maximum service temperature of 2430 F, but exhibits cold brittleness below 750-1200 F after service temperatures above 1000 F. Common uses are high temperature furnaces, radiant heaters, quartz heaters, and heating elements for toasters.

| Packaging Detail:our standard export seaworthy packing is as follows: wraped with"plastic film"as well as "waterproof paper" to prevent the moist while on sea,final loaded n wooden case or pallet to reduce the pressure while loading as required |

| Delivery Detail:25days after receiving deposit |