ISO / CE Approved Vibrator Feeder / Vibrating Screen Feeder / Vibrating Feeder

| Condition:New | Application:Mining, Building, Chemistry, etc | Power Type:Electric | Capacity(t/h):80-1000t/h |

| Place of Origin:Henan China (Mainland) | Brand Name:DongFang | Model Number:GZD/ZSW series | Power(W):22 |

| Dimension(L*W*H):6082*2580*2083 | Weight:6647kg | Certification:ISO9001:2008, CE | Warranty:2 years |

| After-sales Service Provided:Engineers available to service machinery overseas | Name:Vibrating screen feeder | Max. feed size:500-1100mm | Rotate speed:800-900r/min |

| Capacity:90-1200t/h | Power:11-55kw | Dimension:4282*1800*2150 | Spare parts:Supply |

| Training:Supply | Color:Customized |

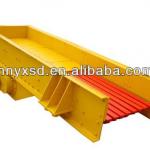

Vibrator Feeder/Vibrating Screen Feeder/Vibrating Feeder

1. Application of Vibrating Feeder

Vibrating Feeder is a kind of linear direction feeding equipment. It features smooth vibrating, reliable operation, long service life and being suitable for feeding. Vibrating feeders are widely used in mining, building-material, silicate andchemical industry in the crushing and screening plants.In the Sand-Stone production line, vibrating feeder can send materials to crusher evenly and continuously and at the same time, it can screen materials roughly.Vibrating feeder can be used in these areas such as metallurgical industry, coal mining industry, mining-selecting, building, chemical and grinding industry, etc.

2. Features and Benefits of Vibrating Feeder

Vibrating feeder enjoys simple structure, stable vibrating, even feeding, good continuous performance, adjustable excitation force, etc. Its flow rate can be conveniently changed and controlled.2. It adopts eccentric block as the excitation source and features low noise, low energy consumption, good adjusting performance, and no material splashing.3. Closed type vibrating feeder can prevent the pollution of dust. 4. The pressure caused by the material to the groove should be reduced to the greatest extend. The effective discharge opening should be smaller than the one quarter of the groove width. The flow rate should be controlled within 6-18m/min. 5. For feeding materials with a large quantity, a fender with enough height should be installed at the outlet. This fender should not be fixed to the feeder since it will affect the performance of the machine.6. For smooth charging, the best discharging angle is 55°-65°.

3. Working Principle ofVibrating Feeder

Vibrating feeder consists of vibrating frame, spring, vibrator, motor vibrating device and motor. The vibrator is made of two fixed eccentric shafts whose gearsare jogged. When installation, the two gears must be jogged according to the sign. Through drive of the motor, the two eccentric shafts start rotating to producea linear huge power which forces the feeder to vibrate. Through the vibration,the materials will slip and sling on the funnel, moving forward, when the materials pass the screening part, smaller parts will fall down, and avoiding the furthercrushing, so screening purpose can be reached.

4.Main Technical Parameter of Vibrating Feeder

Model | Max. feed size (mm) | Rotate speed (r/min) | Capacity (t/h) | Power (kw) | Dimension (mm) | Weight (kg) |

ZSW380×95 | 500 | 800 | 90160 | 11 | 3970×1740×2180 | 4675 |

ZSW420×110 | 580 | 800 | 120240 | 15 | 4282×1800×2150 | 5880 |

ZSW490×110 | 580 | 800 | 120280 | 18..5 | 5000×1800×2150 | 6900 |

ZSW590×110 | 630 | 800 | 200350 | 22 | 6000×1800×2150 | 8700 |

ZSW500×130 | 750 | 800 | 140500 | 30 | 5206×2842×2457 | 8600 |

ZSW560×130 | 750 | 800 | 140500 | 37 | 5806×3142×2457 | 9120 |

ZSW600×130 | 750 | 800 | 400560 | 37 | 6206×3142×2457 | 11800 |

ZSW500×160 | 1000 | 900 | 2501000 | 45 | 5206×3142×2457 | 14120 |

ZSW560×160 | 1000 | 900 | 2501000 | 45 | 5806×3142×2457 | 16700 |

ZSW600×150 | 1100 | 900 | 4501200 | 55 | 6206×3132×2757 | 19200 |

Dongfang Company Overview:

We Dongfang Business principle: Quality first, Reputation first , we will committed to provide high quality and durable products for every customer.

Welcome your visiting!

| Packaging Detail:standard container, nude packs or in bulk. |

| Delivery Detail:25-30 working days |