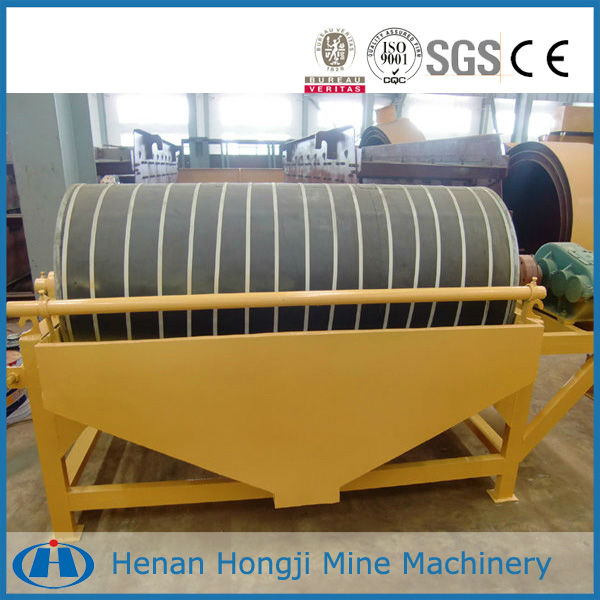

ISO Approved tin ore magnetic separator for concentrating iron ore

| Condition:New | Type:Magnetic Separator | Place of Origin:Henan China (Mainland) | Brand Name:HongJi |

| Model Number:CTB,QCG,GSC | Power(W):1.1-15KW | Dimension(L*W*H):Depend on models | Weight:Depend on models |

| Certification:ISo9001:2008 | Warranty:12 months | After-sales Service Provided:Engineers available to service machinery overseas | Cylinder Size(mm):Depend on model(Like 600 *1800) |

| Rotation speed of Cylinder(mm):0-46mm | magnetic field strength:100-600GS/1000-5000GS/13000-15000GS | Capacity(t/h):Depend on models |

Tin ore magnetic separator

Introduction of magnetic separator:

Magnetic separator is used to selecting kinds of ores which are magnetite, pyrrhotine ,calcined ore,limetite and so on. While, according to different specifications, magnetic separator has wet magnetic separator, dry magnetic separator and a new type high gradient magnetic separator.

Wet magnetic separator:

Magnetic Separator is widely used in mineral processing, coal washing and chemical industry, for sorting the wet particle

size of 6-10mm. The strong magnetic minerals and magnetic minerals are divided into two kinds of material: non-magnetic

material and magnetic material. Magnetic separator is suitable for wet magnetic separation of materials such as magnetite,

calcined ore, etc. and it can remove the iron in the coal, non-metal and construction industries.

Main technical parameters of wet magnetic separator:

Dry magnetic separator:

The series dry magnetic separator (from single cylinder to four cylinders) can eliminate iron from dry powder continuously

and automatically. Its magnetism is designed uniquely. The magnetic source is permanent magnetic NdFeB materials

which is the king of magnetism. It has strong magnetic field and attractive force, and high rate of eliminating iron. It also

has the characteristics of maintenance-free, energy-saving, safety and reliability. We can control the quantity of materials

of different particles. It can be used in abrasive tools, refractory, nonmetallic mineral, carbon, food, feed, chemical

materials, etc.

|

Main technical parameters of dry magnetic separator:

| Model | Cylinder Size (mm) | Magnetic induction | Power (<=kw) | Cylinder speed (<=m/s) | Weight (kg) | Remarks |

| GSC-618 | 600x1800 | 1000-5000 | 2.2 | 46 | 3320 | It allows cutomized design for magnetic field strength and specification |

| GSC-718 | 750x1800 | 1000-5000 | 3.0 | 46 | 2500 | |

| GSC-7520 | 750x2000 | 1000-5000 | 3.0 | 46 | 3870 | |

| GSC-7522 | 750x2200 | 1000-5000 | 4.0 | 46 | 4050 | |

| GSC-7526 | 750x2600 | 1000-5000 | 4.0 | 46 | 4420 | |

| GSC-9018 | 900x1800 | 1000-5000 | 5.5 | 36 | 5750 | |

| GSC-9024 | 900x2400 | 1000-5000 | 7.5 | 36 | 6050 | |

| GSC-10240 | 1050x2400 | 1000-5000 | 11 | 36 | 8300 | |

| GSC-12240 | 1200x2400 | 1000-5000 | 15 | 30 | 12000 |

High gradient magnetic separator:

High gradient magnetic separator is mainly used for recycling weak magnetic metal ores.

High gradient magnetic separator application:

Ferrous metal: recycling feint hematite, hematite, limonite, siderite, ilmenite, manganese,cetc.

Nonferrous metal: separating wolframite, garnet, etc.

Rare metal: recycling tantalum niobite, iron lepidolite, monazite, xenotime, etc.

Nonmetal: decontaminating quartz, feldspar, kaolin and refractory material.

Main technical paraments of high gradient magnetic separator:

| Model | The strength of magnetic field (GS) | Separation Size (mm) | Capacity (t/h) | Power (kw) |

| QCG-2-60-110 | 12000-14500 | 0.4-5 | 2-3 | 1.1 |

| QCG-2-110-150 | 12000-14500 | 0.4-5 | 4-5 | 1.5 |

| QCG-2-150-220 | 12000-14500 | 0.4-5 | 4-6 | 1.5 |

| QCG-2-220-320 | 12000-15000 | 0.4-5 | 5-7 | 3.0 |

We also can supply the whole magnetic separating process:

If you interests these equipments,please contant us.

Mobile:0086-15038331897

Tel:+86-371-67668558

Fax:+86-371-67662768

Skype:hongjiapple.ye

Hongji Honors:

| Packaging Detail:Standard packing, Seaworthy packing, or as required |

| Delivery Detail:30 days after signing contract |

![[Photos] Sentai supply quality magnetic separator machine with good design](http://www.machineto.com/img/thumb/10/31/49/10314964.jpg)