Iron Ore, Gold, Lead Zinc Magnetic Separator Machine Widely Used In South Africa

| Condition:New | Type:Magnetic Separator | Production Capacity:10-15t/h | Place of Origin:Henan China (Mainland) |

| Brand Name:XKJ | Model Number:CTB0612 | Voltage:380V | Power(W):2.2kw |

| Dimension(L*W*H):2280x1300x1250 | Weight:1.2t | Certification:ISO9001:2008 | Warranty:For one year |

| After-sales Service Provided:Engineers available to service machinery overseas | Magneic induction:1200-1500Gs | After -sale service:whole using life | Color:Red, blue, as per your requirement |

| Feeding size:0.4-0 mm | Spear parts:For whole using life in lower price | Wear parts:Supply in lower price for whole using lifer | Design:By our more than 30 years experience engineer |

| Testing run:Guide by our engineer . |

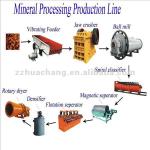

Application of Magnetic Separator Machine:

Magnetic separatoris applicable for wet magnetic separator magnetic, magnetic pyrite, roasted ore and ilmenite with the size less than 3mm. And it also can be used to remove iron for coal,non-metal mineral and building materials etc. Magnetic system is made by compounding the superior ferrite materials with rare earth cobalt-magnet. The magnetic introduction is 100-600mT. According to client's requirements, we can provide clients with fair current, half fair current and counter current magnetic choice with different magnetic induction. It has the advantages:simple structure, big processing capacity, easy to operate and maintain.

Magnetic separator is divided into wet and dry magnetic separator.

Parameter of Magnetic Separator Machine:

| Model | Diameter (mm) | Length of drum (mm) | Speed (r/min) | Feeding size (mm) | Capacity (t/h) | Power (KW) |

| CTB6012 | 600 | 1200 | <35 | 2-0 | 10-15 | 1.5 |

| CTB6018 | 600 | 1800 | <35 | 2-0 | 15-20 | 2.2 |

| CTB7518 | 750 | 1800 | <35 | 2-0 | 25-35 | 2.2 |

| CTB9018 | 900 | 1800 | <35 | 3-0 | 35-50 | 3 |

| CTB9024 | 900 | 2400 | <28 | 3-0 | 40-60 | 4 |

| CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

| CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | 1200 | 1800 | <18 | 3-0 | 100-150 | 5.5 |

| CTB1224 | 1200 | 2400 | <18 | 3-0 | 120-160 | 7.5 |

Working principle ofMagnetic Separator Machine:

When the ore pulp folw into the magnetic field, the strong magnetic minerals are adsorbed on the surface of the drum. The weak magnetic and non-magnetic minerals are cast off and discharged, while the strong magnetic minerals on the surface of the drum rotate with the drum and will be brought out of magnetic field to complete the sorting operation.

Magnetic Separator Machine Features:

1.Big processing capacity

2.Wide range of separating mineral size

3.High precision of separation, and non-blocking

4.Simple structure, easy maintenance

5.Strong electro power consumption is only 20% of magnetic separator.

Why choose our company machine?

1. We are factory (NOT Dealer)

All machinery fromHenan Xingyang Mining Machinery Manufactoryaremade by ourselves, No trade company make

Commission(many trade companies do not produce the machinery),the lower price with the same goods, good quality, after service can be assured (after service of trade companies will get help from factory).

So please buy from factory.

2. We will do our best to satisfy every customer's needs

Producing high-quality and reliable machines is our first priority, because we know that our success depends entirely on the satisfaction of our customers. We never give-up quality to save cost.

We will leave 5% retention money for 3 months to show our sincerity. You can pay it after the machine go into normal operation.

3. Training & service

Training is FREE to every customer. Whenever you need us, for installation, maintenance, or proper use of our company machines, we will be right there for you. In addition,we provide one-year warranteeto make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.

4. If you are new for this business, I will help you

Many thanks for your trust; we can provide you with the pre-services of design scheme for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments, drilling rig, Loader, trucks, excavators and so on

5. We will recommend a suitable type for you and send you a best quotation

| Packaging Detail:container, as per your requirement |

| Delivery Detail:within 45 days after receive your deposit |