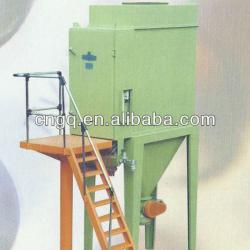

industrial dust collector

| Condition:New | Type:Other | Efficiency:over 99.5 percent | Place of Origin:Yunnan China (Mainland) |

| Brand Name:KMCM | Model Number:YBC | Certification:State | Warranty:12 month |

| After-sales Service Provided:Engineers available to service machinery overseas |

industrial dust collector

YBC Pulse bag type dust collector

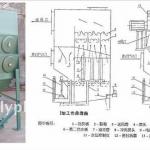

1.Structure :

YBC pulse bag type dust remover is consists of collecting chamber, bearing leg, exhausting system, and pulse counter-spraying & blowing system, in which the collecting chamber includes air intake pipe, guide stop plate, dir & air box, filtering bag, air washing box , examine door, U type pressure gauge, air outtake pipe; bearing leg include support stand, dust hopper; exhausting system includes dust exhausting valve, exhausting sleeve or helix exhausting system; pulse counter-spraying & blowing system includes air bag, safety valve, filtering reducing valve, spraying & blowing pipe, electromagnetic pulse valve.

Filtering bag made from new type anti-dew filter fabric with good function and dust drop easily, convenient for changing, cleaning and maintenance.

Dust exhausting valve exhaust dust through rotating valve core of exhausting valve.

2.Working principle:

The dust air enters the air dust collecting chamber through air inlet and pipe line, then the air expands, and its speed debase, under the gravity action and collision with the guide plate, the large size dust particles will drop into dust hopper. Under the whipping & blowing, the smaller size dust particles will fall to the dust hopper from filtering bag also. After filtering, the clean air will enter air washing box through the inner chamber of filtering bag and venturi, then through air washing pipe, fan and silencer, finally ejected out.

.

In order to prevent the dust particle get into block on the filter bag outside and control the filtering resistance, there sets pulse spraying & blowing system. The filtering bag will be expanded greatly and shrink abruptly, will be attached toshake off thesurface ofdustin the bagoutside.

Thecleaning cycleaccording to theactualsituation ofdust removing system,such as the air with high concentration of dust,humidity,dust concentration,fine particles,multiplebondon the bag,the working resistanceincreases,the cleaning cycletime needs to beshort. But thecleaningtimetoo short,thedustvolumedown,pipelineand thesuctionvelocity isdecreased..

One time spraying & blowing time(pulse width) can be roughly adjusted as 0.1 second, pulse interval will be about 0~30 seconds. Pulse control instrument is set for controlling pulse width, pulse interval and spraying & blowing sequence. Electromagnetic valve is switch for spraying & blowing compressed air, under the control of signal sending by pulse control instrument which will play a very import role together with electromagnetic valve for operation of equipment.

| Packaging Detail:Standard export wooden case packing |

| Delivery Detail:40 days |