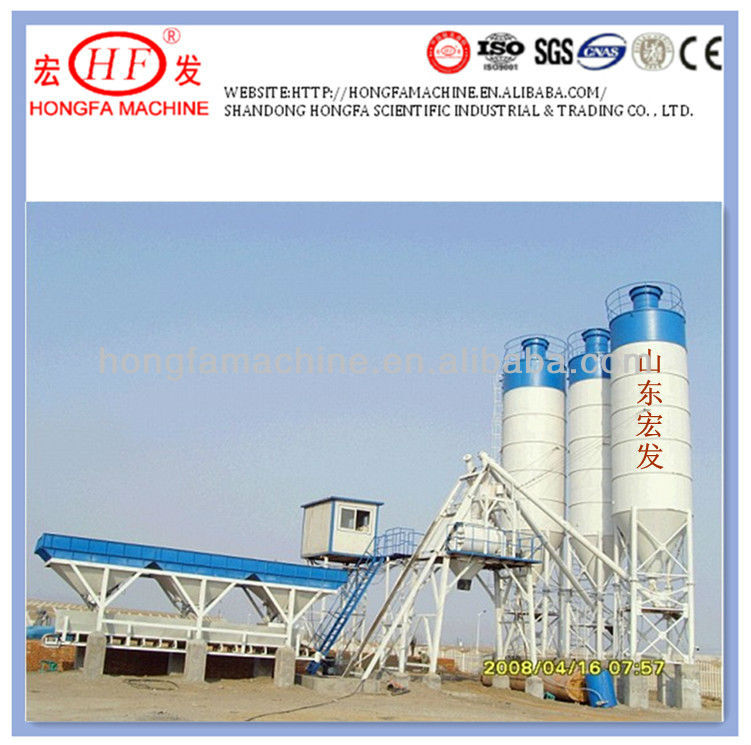

HZS60 automatic ready concrete mixing plant 60m3/h

| Condition:New | Power Type:Electric | Place of Origin:Shandong China (Mainland) | Brand Name:Hongfa |

| Model Number:HZS 60 / HZS50/ HZS75 / HZS120 | Power(W):100kw | Weight:60T | Certification:ISO CE SGS |

| Warranty:one year | After-sales Service Provided:Engineers available to service machinery overseas | Max. Productivity:60m3/h | Max Weighing Value of aggregate:3000kg |

| Max Weighing Value of cement:600kg | Max Weighing Value of water:250kg | Max Weighing Value of additive:50kg | Mixing Power:37kw |

| Hoist Power:15kw | Power of Machine:100kw | Discharge Height:3.8m |

HZS60 automatic ready concrete mixing plant 60m3/h concrete batching plants

Shandong Hongfais thetop leader on manufacturing concrete construction machines with65%market share . We havemore experiencein the lines . please feel free to contact us for more information or need any help , it will be our pleasure to be of service to you .

"Choose world-class machine , ends in Hongfa

Features:

1. Stability and Durability: adapt and apply the most advanced technologies around the world.

2. Reliability: 16years of experiences in manufaturing concrete mixing plants

3. Stationary modular structure, fast and easy installation

4. Sicoma mixer,excellent mixing performance with high efficiency and high productivity

5. Double computers with double controls,easy operation

6. Excellent environmental protection,dust collection system and anti-noise design.

Central Control System

1. The control system of double computers with double controls consists of two industrial computers,one is production control computer and the other is production management computer. The control system has the following functions

2. The management computer is a backup computer for the whole electric control system. When the control computer is out of order,the management computer can be changed into the control computer to control production.

3. Long-distance trouble shooting by internet and teleservice,which greatly improves the users ability to trouble shoot the system.

4. The control room, which is made of colorful shaped steel plates,is capacious,anti-noise and heat insulated.

Excellent Mixing Performance

1. Horizontal twin-shaft compulsory mixer has the strong mixing ability with uniform mixing and high production output. The admixtures are widely mixed by the shafts,and reach the best proportional ratio of uniform.

2. The mixing shafts adapt anti-binding technology to prevent the cement from binding on the shafts.

3. Mixing paddles, arms and blades are made of special high chromium and high manganese alloy materials. The wear resistance of the mixing paddles saves time and cost to replace,and at the same time,improves the machines durability and reliability.

4. The greasing system, which is controlled by central control system,lubricates the greasing points at the fixed position, fixed time and fixed quantity.

5. Decelerating system uses high-speed,synchronized,and closed planetary decelerators.

6. The opening of discharge gate can be adjusted by hydraulic system as per specific requirements.

Technical parameter

| Item | Unit | Parameter |

| Max.Productivity | m3/h | 60 |

| Nominal capacity of mixer | m3 | 1 |

| Max Weighing Value of aggregate | kg | 3000 |

| Max Weighing Value of cement | kg | 600 |

| Max Weighing Value of water | kg | 250 |

| Max Weighing Value of additive | kg | 50 |

| Rating transport capacity of screw conveyor | t/h | 35 |

| Capacity of Cement Cabin | t | 2x100 |

| Mixing Power | kw | 37 |

| Hoist Power | kw | 15 |

| Power of Machine | kw | 100 |

| Weight of Machine | t | 50 |

| Discharge Height | m | 3.8 |

| Aggregate measuring accuracy | % | ≤ ± 2 |

| Water measuring accuracy | % | ≤ ± 1 |

| Cement measuring accuracy | % | ≤ ± 1 |

| Additive measuring accuracy | % | ≤ ± 1 |

| Outline Diemension(LXWXH) | m | 30x10x19.4 |

Cement storage and feeding system----------------------------------------------------------------Optional parts

Cement silo capacity------------------------------------------------------------------30t/50t/60t/80t/100t/

Screw conveyor diameter------------------------------------------------------------Φ219mm/Φ273mm

Concrete mixer model& quantity------------------------------------------------------------------------JS750 , 1 unit

Discharging volume-------------------------------------------------------------------750L

Charging volume-----------------------------------------------------------------------1200L

Mixing cycle-------------------------------------------------------------------------------75s

Max.mixing size--------------------------------------------------------------------------Φ80/60mm

Aggregate batching machine model&quantity---------------------------------------------------------PLD1200, 1 unit

Storage bins quantity------------------------------------------------------------------3or 4 sorts

Aggregate scale hopper--------------------------------------------------------------1200L

Aggregate feeding to mixer by-------------------------------------------------------Hopper

Weighing system principle&quantity-----------------------------------------------------------------------Force sensor, 1 set

Water weighing bunker---------------------------------------------------------------1 unit

Cement weighing bunker------------------------------------------------------------1 unit

Control system type& quantity----------------------------------------------------------------------------------Central control, 1 set

PLC brand--------------------------------------------------------------------------------SIENENS(Optional Part)

Control panel board-------------------------------------------------------------------Buttons ,lights,etc

Electric components------------------------------------------------------------------Relays ,contactors,etc

High- pressure air system quantity----------------------------------------------------------------------------1 set

Air compressor-------------------------------------------------------------------------0.6 MPa

Oil-water separator-------------------------------------------------------------------1 or 2 units

Solenoid valve--------------------------------------------------------------------------1 or 2 sets

Contact Amy Liu to get more information !

Mb: 0086-13960083506 Skype: donghaowen66

Shandong Hongfa Scientific Industrial & Trading Co .,Ltd

| Packaging Detail:In view of the steel raw material, we have taken several steps, firstly, we platform a all-side antirust oil paint, then, a second paint processing, but this time is to be beautiful, will show our brand out .In the process of transport, we mostly adopt nude, because the machine is very high in hardness, and the processed products has a best stability .of course, for those untreated such as bearing we would further packaging. Anyhow, guarantee that the goods be shipped to the destination securely. |

| Delivery Detail:30 days after signing contract |