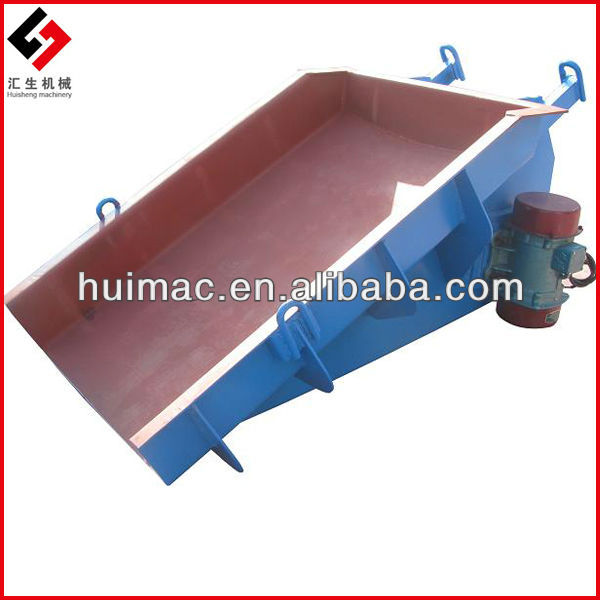

HUIMAC GZG Series Feeding Machine from China with low price

| Condition:New | Application:many fields | Power Type:Electric | Capacity(t/h):30t/h |

| Place of Origin:Henan China (Mainland) | Brand Name:HUIMAC | Model Number:GZG40-4 | Power(W):2*0.25kw |

| Dimension(L*W*H):1337*750*600mm | Weight:171kg | Certification:ISO9001 | Warranty:one year |

| After-sales Service Provided:Engineers available to service machinery overseas | Max feeding size:100mm | Vibrating Speed:1450r/min | Double Amplitude:4mm |

| Color:Customized |

Applications of HUIMAC GZG Series Feeding Machine

- Widely used in metallurgy, coal, chemicals, building materials, ceramics, grinding, food and other industrial and mining enterprises.

- You can feed massive, granular, powder materials from storage silos to affected devices uniformly, quantitatively and continuously.

- It adapted for automatic batching, quantitative packaging and automatic control.

Characteristics of HUIMAC GZG Series Feeding Machine

- It can change the motor speed and control flow, and thus it is convenient adjustment.

- Flow stability, low voice , small power consumption, has no phenomenon of non-washed material.

- While the machine has light weight, small volume, and convenient maintenance characteristics.

- Enlosed structure can be used to keep track of only the dust pollution of the environment.

Structure features ofHUIMAC GZG Series Feeding Machine

Vibration motor is used as vibration source. It has the following advantages compared with other feeding machine:

1.Small size, light weight, simple structure,easy installation and maintenance without rotational parts, no need of lubricant among the different parts, lower operation costs.

2.Based on the theory of sympathetic vibration in mechanism vibration, binary plastid works nearly in the state of critical sympathetic vibration, thus GZG Series feeder costs less power during operation.

3.Since the feeding material volume can be changed, started or stopped instantaneously, the quantity of the feeding materials can be controlled accurately.

4.The control device of GZG series feeder adopts silicon-controlled half-wave Rectification circuit, so the feeding quantity can be steplessly changed during the working by adjustingthe pening angle angl of silicon-controlled.

5.Since the materials in the feeder slot is thrown continually and hop forward in a way of parabolic curve during the feeding, the feeding slot has little wearing.

6.GZG Series auto-synchronous vibrating feeder shouldn’t be used in the explosion-proof working environment.

The Technical Parameters of HUIMAC GZG Series Feeding Machine

| Model | Max Feeding Size | Vibrating Speed(r/min) | Double Amplitude(mm) | Capacity(t/h) | Motor Power(kw) | Size of Funnelmm) | Overall Dimensions(mm) | Weight(kg) | |

| Horizontal | -10· | ||||||||

| GZG40-4 | 100 | 1450 | 4 | 30 | 40 | 2×0.25 | 400×1000×200 | 1337×750×600 | 171 |

| GZG50-4 | 150 | 1450 | 4 | 60 | 85 | 2×0.25 | 500×1000×200 | 1374×800×630 | 202 |

| GZG63-4 | 200 | 1450 | 4 | 110 | 150 | 2×0.50 | 630×1250×250 | 1648×1000×767 | 379 |

| GZG70-4 | 200 | 1450 | 4 | 120 | 170 | 2×0.50 | 700×1290×250 | 1548×1010×787 | 389 |

| GZG80-4 | 250 | 1450 | 4 | 160 | 230 | 2×0.75 | 800×1500×250 | 1910×1188×850 | 563 |

| GZG90-4 | 250 | 1450 | 4 | 180 | 250 | 2×0.75 | 900×1483×250 | 2003×1178×960 | 613 |

| GZG100-4 | 300 | 1450 | 4 | 270 | 380 | 2×1.1 | 1000×1750×250 | 2190×1362×900 | 762 |

| GZG110-4 | 300 | 1450 | 4 | 300 | 420 | 2×1.1 | 1100×1673×250 | 2151×1362×970 | 854 |

| GZG125-4 | 350 | 1450 | 4 | 460 | 650 | 2×1.5 | 1250×2000×315 | 2540×1500×1030 | 1099 |

| GZG130-4 | 350 | 1450 | 4 | 480 | 670 | 2×1.5 | 1300×2040×300 | 2544×1556×1084 | 1117 |

| GZG150-4 | 500 | 1450 | 3.5 | 720 | 1000 | 2×2.25 | 1500×2250×300 | 2794×1776×1220 | 1477 |

| GZG160-4 | 500 | 1450 | 4 | 770 | 1100 | 2×2.25 | 1600×2500×315 | 3050×1850×1110 | 1555 |

| GZG180-4 | 500 | 1450 | 3 | 900 | 1200 | 2×2.25 | 1800×2325×375 | 2885×2210×1260 | 2350 |

| GZG200-4 | 500 | 1450 | 2.5 | 1000 | 1400 | 2×2.25 | 2000×3000×400 | 3490×2400×1220 | 2705 |

| GZG150-6 | 500 | 960 | 5 | 780 | 1080 | 2×3 | 1500×1800×400 | 2500×1864×1412 | 1441 |

| Packaging Detail:suitable packing to the export |

| Delivery Detail:7-15 working days after downpayment |