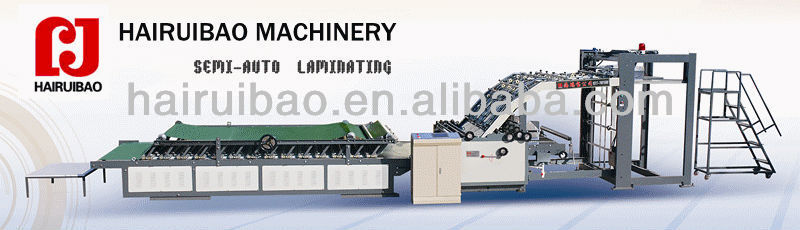

HRB-HII high speed semi-auto flute laminate machine

| Type:Laminating Machine | Condition:New | Application:carton box | Packaging Type:Cartons |

| Packaging Material:Plastic | Automatic Grade:Semi-Automatic | Driven Type:Electric | Voltage:380V |

| Power:7kw | Place of Origin:Hebei China (Mainland) | Brand Name:Hairuibao | Model Number:1300 HII |

| Dimension(L*W*H):10m x2m x2.2m | Weight:3.5T | Certification:CE | product name:HRB-HII semi-auto laminating machine |

HRB-HII high speed semi-auto flute laminate machine

Introduction:

HRBTMJ-H-II type servo machine is based on HRBTMJ-H-I, improved the automatic up and down surface paper system. Surface paper can pile up the height of 1m once time, useing photoelectric automatic up. So this design reduced more time for moving the surface paper.

Main feature:

1. The top paper can pile up the height of 1m once time ,it makes delivery more easier and efficient

2. Adopt PLC & Taiwan servo motor control system, working is more precision and stable,improved the speed, circuit faults can automatically alarm.

3. Using suction feeding automatic of bottom sheet, according to the main machine operating speed, continuous automatic tracking

4. Entire new concept,front gauge registration, position high accuracy, bottom sheet never exceedes the top sheet.

5. Machine uses touch-screen / PLC control system, the circuit system is stable, and can automatically display the failure alarm

6. The automatic replenishment system of glue can be added automatically during glue losses, and recycling with the glue to avoid loss of waste;

7. The scientific design of the metering roller speed to ensure the glue evently on the same time, to avoid rejection of glue at high speed.

8. Using the rubber roller cleaning to make cleaning thoroughly, and so that the back of the corrugated cardboard never gets glue, and eliminating the trouble of frequent replacement of blade.

9. Floating removable press, to ensure that laminated paper will not be crushed, and also keep the cardboard smooth and straight; unilateral adjustment by way of adjustment worm roll lamination pressure for quick

10. Control of water tank cleaning cycle using an independent method, clean, hard rubber product;

11.Suitable for color top sheet 175-500g and A/B/C/D/E/F corrugated paper laminating;

Technological parameter:

| Model | HRBTMJ-1300H-II | HRBTMJ-1500H-II | HRBTMJ-1600H-II |

| Max size of cover face | 1300mmX1100mm | 1500mmX1250mm | 1600mmX1250mm |

| Mix size of cover face | 360mmX360mm | 360mmX360mm | 360mmX360mm |

| Economic speed | 0-100 piece/min | 0-100 piece/min | 0-100 piece/min |

| Precision | ±1 | ±1 | ±1 |

| Power | 7kw | 7kw | 7kw |

| Size | 10m x 2m x 2.2m | 10m x 2.2m x 2.2m | 8.8m x 2.3m x 2.2m |

| Weight | About 3.5T | About 4.0T | About 4.0T |

1.vacuum suctoon-type feeding system, feeding paper accurately,cycle stackingplanes,so more efficient.

2.Adopt PLC control system, working is more precision and stable,improved the speed, circuit faults can automatically alarm.

3.This machine adopts Taiwan servo motor,instead of the break,clutch and electronic eye, realized PLC & servo single control independently.

4.feeding corrugated paper adopt suction automatic feed,feeding speed is automatic synchronous with surface paper.

5.adopt elastic face set position,positioning precision. the corrugated paper never pull head.

6.automatic gluing, automatic feeding glue, and the glue can be used circulatory, avoid glue waste.

7.Roller design scientifically, avoid glue fly out when the speed is high.

8.Pressure rollers adopt unilateral adjustment, convenient and fast.

9.Rocker controls wash roller's lifting, easy cleaning.

10.automatic counter , easy recording the amount you have been worked.

HRB-H VACUUM SUCKING SEMI-AUTO FLUTE LAMINATOR

Factory picture

whole machine analysis picture

Any inquiry, don't be hesitate to contact me.

Thanks & best regards,

Evan Ning

| Packaging Detail:container |

| Delivery Detail:Within 15 days after receiving the deposit |