Hot selling high efficient silica sand rotary dryer

| Place of Origin:Henan China (Mainland) | Brand Name:Fengde | Model Number:silica sand rotary dryer | Condition:New |

| After-sales Service Provided:Engineers available to service machinery overseas | input tempreture(C:≤800 | Certificate:ISO CE | Capacity:0-75t/h |

| Factory Visit:Welcome | Warranty:12 months | Installation:Under the guide of our engineer | Spare parts:supply |

| OEM:yes | Color:as your demand | Drawings:provide |

Hot selling high efficient widely silica sand rotary dryer

Brief introduction of silica sand rotary dryer:

Dryer machine, which is also known as rotary dryers, limestone dryer, or cement rotating dryer, is the key equipment to dry different materials with humidity or granularity in various fields. According to its shape, it is also called drum dryer. China is one of the major countries to manufacture such dryer machines, and therefore, China dryer is the best-selling product in the world.

The working principle of silica sand rotary dryer:

The dryer is made up of a large, rotating cylindrical tube, usually supported by concrete columns or steel beams. The dryer slopes slightly so that the discharge end is lower than the material feed end in order to convey the material through the dryer under gravity. Material to be dried enters the dryer, and as the dryer rotates, the material is lifted up by a series of internal fins lining the inner wall of the dryer. When the material gets high enough to roll back off the fins, it falls back down to the bottom of the dryer, passing through the hot gas stream as it falls.

This gas stream can either be moving toward the discharge end from the feed end (known as co-current flow), or toward the feed end from the discharge end (known as counter-current flow). The gas stream can be made up of a mixture of air and combustion gases from a burner, in which case the dryer is called a direct heated dryer. Alternatively, the gas stream may consist of air or another (sometimes inert) gas that is preheated. When the gas stream is preheated by some means where burner combustion gases do not enter the dryer, the dryer known as an indirect-heated type. Often, indirect heated dryers are used when product contamination is a concern. In some cases, a combination of direct-indirect heated rotary dryers are also available to improve the overall efficiency.

Application of silica sand rotary dryer:

Concurrent flow drying type | |||

| |||

Countercurrent flow drying type | |||

| |||

Indirect heating type rotary dryer | |||

|

Performance features of silica sand rotary dryer:

The machine mainly consists of rotary machine, raising plate, transmission device, supporting device and seal rings and other components. The dry machines in our company use the new-type raising plate, which has the functions of guiding, even flow, raising materials etc. The raising plate can make the materials be distributed uniformly to the cross profile in the dryer machine. The material curtain is at the state of thin, even and complete, with completely touching with the hot air flow to reach the purpose of making full use of the heat energy. The consumption of coal and electricity of the dryer in our company can be lower 10% to 15% than the normal dryers, with the production ratio higher than 10% to 15%.

The main technical data of silica sand rotary dryer:

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity (%) | Highest Inlet Air Temperature (°C) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

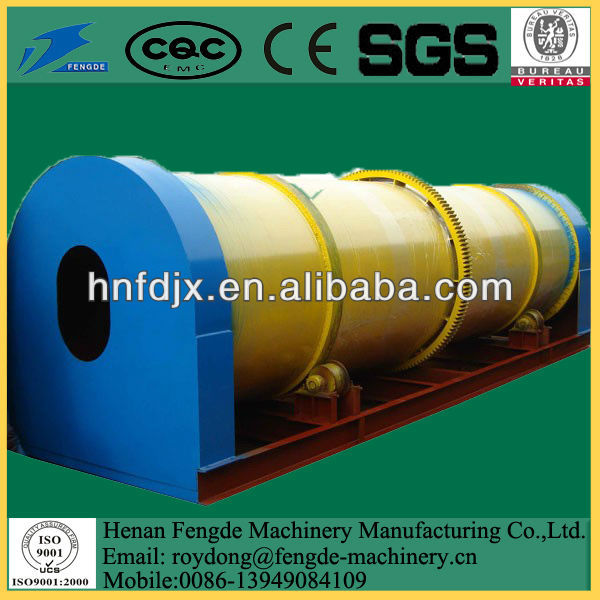

Pictures of silica sand rotary dryer:

The sketch of silica sand rotary dryer:

Transportation of silica sand rotary dryer:

The producing sites of silica sand rotary dryer:

Contact:

More information, contac us freely. We are one of the most professional manufacturers of silica sand rotary dryer.

| Packaging Detail:Export standard or nude packing,spare parts in wooden case or according to your demand |

| Delivery Detail:30 days after receiving the deposit |