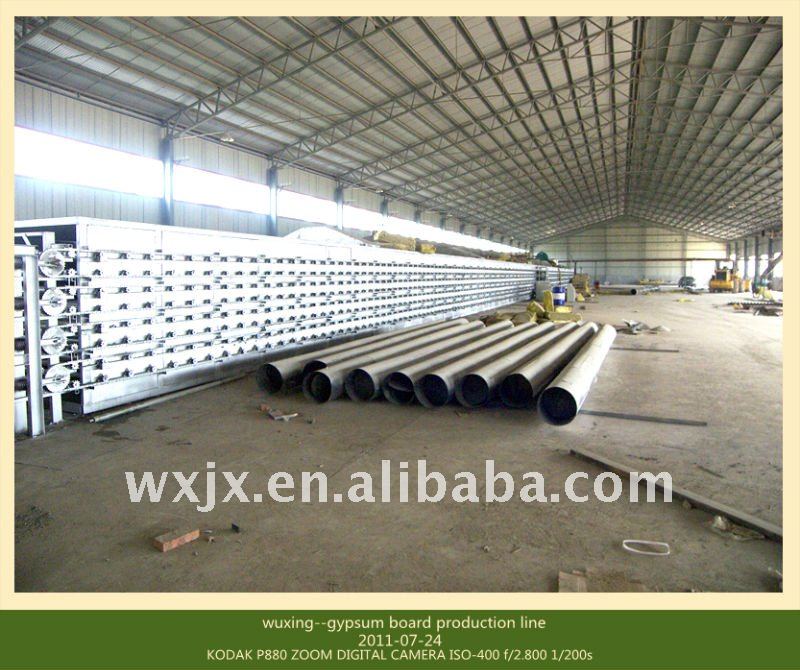

hot oil conducting type--gypsum board equipment line

| Place of Origin:Hebei China (Mainland) | Brand Name:wuxing | Model Number:wx-180 | name::gypsum board equipment line |

| fuel::coal ,natural gas,disesel | board thickness::7-15mm | width::1220mm | need worker::26-39 |

| type1::hot oil conducting type | type2::hot air type | brand::china famous brand--wuxing | export year::10 year |

| business type::manufacturer |

plaster board equipment line

------------------------------------------------------------------

1, Market forecasting

The gypsum board is light, fire-resistant,warm,insulated and moisture resistance and it is the necessary material in the ceiling and interior decoration. The gypsum board becomes popular since 1979. In the recent years, the gypsum board capacity rises year by year and become the pillar industry. With the adjustment of national Industry Policy, the newly decoration material will be used in the big and small cities as well as home decoration. Thus, the gypsum board has spacious potential market in these years.

2,Required conditions

Take the 4 million square meter as an example, it should meet the following standard:

(1)Electricity supply The total power supply should be 300KW(including the residents electricity).

(2)Water supply 6 Cubic Meters/hour

(3)The total floor area is about 7000 square meters,workshop about1500 square meters.

(4)Have good transport and telecommunication services.

3,Environment Protection

The main ingredient is gypsum powder(natural gypsum,ardealite). All the process is equipped with dust-collect system, won’t pollute the environment. The heat supply device is hot-oil conductive boiler; its emission concentration meets the national standard.

4,The gypsum board process is as following

Plaster hopper---mixing---shaping---freezing---first cutting---drying ---detailed cutting---packing---finished products

5,Raw material consumption(square meter) gypsum powder 6.8kg,shielding paper 0.5kg,coal0.9kg,starch 40g,foaming agent 5g,glue 10g,electricity 0.3kwh

6,staffing take the 4 million S.Q.M. production line as an example,it will need office

staff 5 people and workers12 people (namely 17 people) per shift.

7,Construction Progress Project Approval,Process Layout,civil engineering

equipment selection,production installation and commissioning. It will need about 5

months.

8,conclusion

a) It is Newly green decoration material, little investment, high reward, suitable for small and medium-sized company.

b) The gypsum board has a potential market; it is the necessary internal decoration material. It will develop very quickly in the near future.

c) Little investment, high reward and little period.

| Packaging Detail:CONTAINER |

| Delivery Detail:60 DAYS |