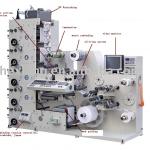

High speed flexo printer slotter die cutting carton printing machinery

| Type:Flexographic Printer | Condition:New | Plate Type:Gravure | Place of Origin:Hebei China (Mainland) |

| Brand Name:zhenhua | Model Number:zh | Usage:Paper Printer,Card Printer,Tube Printer | Automatic Grade:Automatic |

| Color & Page:Multicolor | Voltage:380 | Gross Power:20kw | Weight:7t |

| After-sales Service Provided:Engineers available to service machinery overseas |

Quick Details

| Type: | Flexographic Printer | Condition: | New | Plate Type: | Gravure |

| Place of Origin: | Hebei China (Mainland) | Brand Name: | zhenhua | Model Number: | GYK |

| Usage: | Paper Printer,corrugated carboard printing and slotting | Automatic Grade: | Automatic | Color & Page: | Multicolor |

| Voltage: | 380v | Gross Power: | 20kw | Weight: | 7T |

| Driven Type: | electricl | Colors: | one to four colors is option | Packaging Type: | Cartons |

| Packaging Material: | paper |

Packaging & Delivery

| Packaging Detail: | wood packing and plastic packing |

| Delivery Detail: | within 30workdays after receive deposit |

Specifications

Specifications:

1.carboard corrugated colors printing and slotting machine.

2.chain push feed and auto feeder can be added .

Specification:

1.Flexo printing

2.The system control by computer

3.Option for kick and leading edge feeding

4.Automatic operation

Function and Characteristics:

ü The electric appliances of a whole machine adopt the excellent product by the domestic products and computer software are used in the whole machine with stable and reliable quality; human-computer interface, computer order storage, convenient operation and faster order update.

ü Adopting helical gear driving, the gears are made from high frequency quenching and processing by high precision grinding machine to maintain high topping precision after long using.

ü The gears adopt shower type circular lubricating.

ü All transmission axles and rollers are made by high-quality steel, and processed through tempering and dynamic balance; plated with rigid chrome and grinded surface.

ü All transmission parts (connected with the axles and gears) adopt the hand-free connecting ring to eliminate the interval, suitable for long-term high-speed running

ü All transmission bearings adopt strengthened model bearing, equipped with dustproof windtight parts and the oiling, handy to maintenance, lasting for longer using.

ü The whole machine undergoes automatic spray lubrication, with intuitionistic showing facilities and double oil pipe balance system.

ü The whole machine runs with the adjustment presetting function, feeding, printing, slotting, die cutting all featuring auto- zeroing and memory automatic reposition.

ü The whole machine working interval adjustment adopts fast spanner-free adjustment and the electromagnetic brake system with the worm wheel and worm setting operates fast and conveniently.

ü · The mainframe chooses control by frequency conversion, with more stable and energy-saving for start-up and running.

ü · Option for the vacuum adsorption, kick feeding or leading edge feeding.

ü · Optional equipments: ceramic anilox roller, leading edge feeding system, remote computer diagnosis system, stacker.

Main technical parameter:

serial | name of parameter | unit | secification | ||||||

1200×2000/2400 | 1400×2000/2400/2800 | 1650×2400/2800 | |||||||

| 1 | Inboard width | mm | 2400 | 2800 | 2400 | 2800 | 3200 | 2800 | 3200 |

| 2 | Max.coverage size | mm | 1270×2200 | 1270×2600 | 1470×2200 | 1470×2600 | 1470×3000 | 1730×2600 | 1730×3000 |

| 3 | Min.coverage size | mm | 320×640 | 320×640 | 400×720 | 400×720 | 400×720 | 550×800 | 550×800 |

| 4 | Max.printing area | mm | 1200×2000 | 1200×2400 | 1400×2000 | 1400×2400 | 1400×2800 | 1650×2400 | 1650×2800 |

| 5 | Skip feeding | mm | 1400×2000 | 1400×2400 | 1600×2000 | 1600×2400 | 1600×2800 | 1850×2400 | 1850×2800 |

| 6 | Max.speed | Pieces/min | 150 | 140 | 120 | ||||

| 7 | Running speed | Pieces/min | 120 | 120 | 100 | ||||

| 8 | Topping precision | mm | ±0.5 | ±0.5 | ±0.5 | ||||

| 9 | Slotting precision | mm | ±1.5 | ±1.5 | ±1.5 | ||||

The feeding part:

- Adopt leading edge paper feeding, frequency control of speed regulation;

- Leading edge feeding with vacuum adsorption in operation platform, ensure bent or warped cardboard feeding smoothly

- Light-operated counter pre-set processing quantity;

- Installed with top suction device which keeps printing plate from getting dirty;

- Feeding through biax to ensure paper feeding precision.

The printing part:

Electric separating and connecting, Pneumatic locking, Pneumatic Lifting plate; - Add separating positioning device;

- Electric planetary phase system with high precision and long life;

- Supplying ink by pneumatic membrance pump, ink cup shows ink level, anilox roll will separate pneumatically when machine stops, even ink automatically

Sloting or die cutting part:

- Electric separating and connecting, pneumatic locking

- Electric phase adjust, digital display, input numbers to adjust;

- Slotting knives adopt linkage of four knives;

- Electric box-height adjustment.

- The die-cutting part:

- Rubber cushion roller axial lateral movement automatically, pneumatic lift, overrunning clutch formation, import rubber cushion with long life and durable;

- The lower roller adopts electric planetary phase, axial adjustment, adjusting range is 10mm

- The lower roller diameter porous, for the use of installing the wooden die;

- The lower roller can be matched with four linkage die-cutting tool apron, used for slotting. (electable)

| Packaging Detail:can according your inquiry |

| Delivery Detail:1-2month |