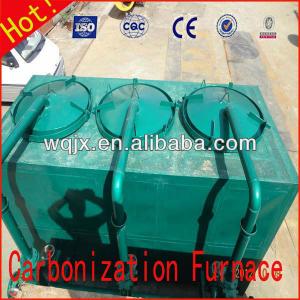

High quality, high capacity and smokeless carbonization furnace, wood carbonization furnace, briquette carbonization furnace

| Condition:New | Type:Air Flow | Application:Wide | Place of Origin:Henan China (Mainland) |

| Brand Name:Wanqi | Model Number:THL | Effective Volume:4 cubic meter | Dimension(L*W*H):2.8*2*2(m) |

| Weight:3.5, 4, 5 t | Voltage:380V | Power(W):1.5 kw | Certification:CE, ISO |

| Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas | carbonizing ratio:88-99% | Operation::Easy and simple |

| price::Negotiation | raw material::wood logs/branch,bamboo,briquettes | After-sales Service Provided::Engineers available to service machinery | Shape::Briquette or as your requirements |

| Application::Carbon waste wood and others | Installation::Engineer Guide | Output::500kg/8hours | material::steel and refractory brick |

High quality, high capacity and smokeless carbonization furnace, wood carbonization furnace, briquette carbonization furnace

The features of Carbonization furnace

The advanced smokeless and energy-saving carbonization furnace has been equipped with High-grade filter, making the stove smokeless and environment friendly after the fast decomposition of moisture and tar in the smoke. It has added gas-smoke retrieving plant based on the original model. The recovery gas-smoke is smokeless and ignitable, which can be used for warming, cooking and also dryer.

The application of carbonization furnace

Charcoal carbonization furnace is the ideal equipment for wood briquettes to have anoxic distillation carbonization. The final products charcoal briquette bars can be used for heating furnace, industrial boilers, biomass power plant. Barbecue and so on.

The finished products

Advantages

1.Unique structure;

2.Environmental friendly;

3.Advanced carbonization technology;

4.Great carbonizing ratio (increased from about 88% to 99%)

Carbonization stove adopt superior purifying technology, and is made from special high temperature resistant material, and show the features of stable and wear well, freeing from oxidation and deformation, superior insulating property, easy operation, safety and reliable, no carbonization blind spot with double chimney, and the finished products ratio are more than 95%, labour and time saving, and one person can operate several carbonization stove simultaneous.

The instruction of carbonization furnace

1.The carbonization of the old-type furnace takes advantage of spontaneous combustion

of biomass briquettes. But the new-type furnace adopts the dry distillation of charcoal technology and also the output charcoals are with good quality and show

metallic luster.

2. The production of old-type is sporadic, and the new type is continuous which improves the production efficiency to a great

extent.

3. The old-type makes plenty of heavy smoke, even if with the cooling treatment, it still brings the serious air pollution.

Different from the oldtype furnace, the newtype does not exhaust the heavy smoke from the carbonization process to the air,

oppositely, it collects. The smoke goes intothe burner through the pipes and burns as fuel gas for recycling use, to reach the aim

of replacing the normal fuel and continue the carbonizing process.

The design of new-type furnace avoids the air pollution of heavy smoke exhausted.

4. The operation of oldtype is quite complicated, before carbonization, the briquettes need to be put properly which wastes too much time and labour.

However, the briquettes can be put irregularly and then process carbonization directly, saving much time and labour.

5. The production efficiency of the oldtype is low. Every 24 hours, the output of 5m³furnace is only around 1 ton. By contrast, due to the design of continuous production,

the new-type furnace can produce around 200 kg charcoals every 1-2 hours, The efficiency of the new type is completely 4 times more than the old-type, which greatly reduce the expenses spent in a great amount of old-type equipments when target capacity is high.

Technical Parameters

| Model | Tech spec |

| THL-4 | Output: 500kg/8hours Carbonizing time:8hours Carbonizing rate:99% Overall size: 2.8*1.8*1.8(m) Weight(t):3.5 |

| THL-8 | Output: 1000kg/8hours Carbonizing time:8hours Carbonizing rate:99% Overall size: 4*2*2(m) Weight(t):5 |

The certifications

About our company

Zhengzhou Wanqi Mechanical Equipment CO., Ltd. Is a production of Clay Brick Machine, Charcoal Machine, Briquette Machine, Drying machine, set the development, production, sales as one of the jointstock enterprises.The corporate headquarters is located in Gongyi City,East New District,covering an area of about 30,000 square meters,including several wholly owned subsidiary,its domestic sales exceeded 50 million (RMB),and exports worth up to 2 million dollars per year since its inception in 1990, the company adhering to the modern enterprise of scientific management methods, the company has introduced the United States, Germany, Japan, Australia and other countries of advanced technology and process to establish the international advanced production lines and first-class modern detection base, Seiko manufacturing, continuous innovation, rapidly expanding to become a shining pearl of China's machinery manufacturing industry.

The Pre-sale service

We send experienced engineers to your country ,who selects the site of the project and make the process design according to your project specific conditions and special requirements. then designand manufacture the best machines for your project , and make sure the machines meets your project requirements to the maximum and meets the upgrade space of production increasement in thefuture.

The sale service

Accompany you to complete the acceptance of the equipment, and help draw up specific construction schemes and detailed process

After-sales service

The company send the experienced engineer to on-site guidance of equipment installation, commissioning and train professional technical personnels for you.

For more information , pls feel to contact with me!

| Packaging Detail:In standard wooden cases |

| Delivery Detail:Within 10 days after we received your deposit |