high quality flake ice machine for cooling

| Condition:New | Capacity:0.5-60tons per day | Place of Origin:Guangdong China (Mainland) | Brand Name:CBFI |

| Model Number:BF Series | Ice Shape:Flake Ice | Voltage:220V/3Ph/60Hz,380V/3Ph/50Hz | Certification:CE |

| Flake Thickness:1mm-2mm | Compressor:Germany Bitzer/America Copeland | Expansion valve:Denmark Danfoss | Solenoid valve:Italy Castal |

| PLC:Germany Siemens | Electric components:Korea LG | Refrigerant:R22/R404a | Cooling way:Water cooling/Air cooling/Evaporative cooling |

| Daily capacity:0.5-60tons |

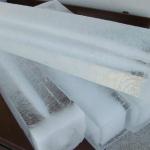

Flake Ice Machine

Application:

Commercialflake ice machine is widely used in supermarket preservation, seafood restaurant, food processing, fruit and vegetable preservation, make the seafood, fresh meat and meat products more fresh.

Industrialflake ice machineis widely used in food processing, chemical manufacturing, bio-technology, wine industry, fruit and vegetable preservation and mine cooling, etc.

ice flake machine with cold room

Design Technology Material

Sea water flake ice machineis designed with intelligent PLC control system, stable running,high -efficiency and simple maintenance.

Our evaporators are made up of stainless steel 304. Its evaporating area is greatly expanded and the ice is more beautiful and dryer by its inner spiral chute design. So it never distorts even long time working in low temperature and low pressure, which greatly increase the working life of the flake ice machine system.

| 01:Motor | |

| 02:Refrigerant runner | |

| 03:Water inlet | |

| 04:Decelerator | |

| 05:Ice skate | |

| 06:Water sprinkling pan | |

| 07:Principle axis | |

| 08:Water sprinkler | |

| 09:Water return pipe | |

| 10:Ice freezing surface | |

| 11:Insulation layer | |

| 12:Ice outlet | |

| 13:Low water pan | |

| 14:Stainless steel wrapper sheet |

Theevaporatorworkers by way of insides scratching and remains unmoved while the knives scratch ice inside wall, the supply of refrigerant keeps constant and unleaked for improved stability of operation.

This machine is made of low temperature quality alloy with reasonable piping design for efficient heating transfer, which can not only improve effectiveness of cold-produce and decrease the running cost, but also can reduce the space requirement and weight and so the disposable investment.

The ice knife works by way of spiral and rolling. Compared with fixed ice knife, it has advantages of smaller resistance, lower power consumption, no noise emission and powerless ice.

Feature

1.The temperature of ice is lower and it can reach 8 celsius degree below zero

2.Ice is dry and transparent, good looking shape, non-caked, good mobility and sanitary.

3.It has the flake shape so that it has big contact area with refrigerating products and the effect is excellent.

4.Flake shape and no sharp edges, cannot destroy refrigerating products and it is beneficial for storage and transportation.

5.The thickness of flake ice is 1mm-2mm. No need to crush and can use at any time.

Flake Ice Machine technical parameters:

| NO. | Production | capacity of refrigeration | Weight of Machine | Machine Dimension |

|---|---|---|---|---|

| -- | Ton/D | Kw | kg | L*W*H(mm) |

| BF500 | 0.5 | 3.75 | 160 | 1220*900*1000 |

| BF1000 | 1.0 | 8.85 | 210 | 1300*960*1200 |

| BF2000 | 2.0 | 17.84 | 360 | 1500*1200*1350 |

| BF3000 | 3.0 | 24.15 | 1000 | 1800*1250*1400 |

| BF5000 | 5.0 | 35.10 | 1100 | 2100*1250*1500 |

| BF6000 | 6.0 | 45.85 | 1100 | 2500*2040*2200 |

| BF8000 | 8.0 | 42.70 | 1300 | 2100*1250*1500 |

| BF10000 | 10.0 | 76.10 | 1500 | 2300*1750*1740 |

| BF15000 | 15.0 | 110.9 | 3200 | 3200*2100*2000 |

| BF20000 | 20.0 | 151.0 | 4200 | 3400*2200*2560 |

| BF25000 | 25.0 | 180.0 | 5000 | 3800*2300*2560 |

| BF30000 | 30.0 | 214.2 | 6000 | 4500*2300*2800 |

| BF40000 | 40.0 | 226.1 | 7500 | 7800*2100*2480 |

| BF50000 | 50.0 | 268.1 | 10000 | 5000*2300*3000 |

| BF60000 | 60.0 | 278.4 | 12000 | 5500*2300*3200 |

Before shipping, we test our products and check all parts!

| Packaging Detail:1. Standard wooden case. 2. Completely ice machine contain: ice machine, cooling tower, water pump, water pipes and water pipe fittings. 3. Machine come into use, customer only need prepare power for the machine. 4. All required components for install the machine will be provided. |

| Delivery Detail:25 working days |