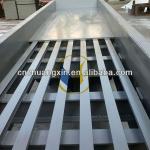

High quality Apron Feeder Pan Converyor,Granite Mining Feeder

| Condition:New | Application:Mining Feeder,Iron ore,stone,coal,Ore,mine,coal,stone,cement | Power Type:Electric | Capacity(t/h):30-300TPH |

| Place of Origin:Jiangsu China (Mainland) | Brand Name:Tianda | Model Number:BW Plate-Type | Power(W):11Kw-45Kw |

| Weight:15t-83.4t | Certification:ISO9001 | Warranty:24 months | Maintainance:Easy |

| Installation:Engineer's Guide | Production Effeciency:High | Mining Feeder:Apron Feeder BW Platy-Type | Color:Customized |

Model BW plate type Apron Feeder,Granite Mining Feeder

Description

The BW series Apron feeder which is made by our company is suitable for using, transferring, mixing and other process flow of the mining, cement, Chemical and the metallurgy industry.Especially transporting the bulk, high temperature and the incisive materials, and can be operated reliably in open-air and moist and so on the adverse circumstances.

Apron Feeder Working Principle

Apron feeder consists of vibrating frame, spring, vibrator, motor vibrating device and motor. The vibrator is made of two fixed eccentric shafts whose gearsare jogged. When installation, the two gears must be jogged according to the sign. Through drive of the motor, the two eccentric shafts start rotating to producea linear huge power which forces the feeder to vibrate. Through the vibration,the materials will slip and sling on the funnel, moving forward, when the materials

pass the screening part, smaller parts will fall down, and avoiding the furthercrushing, so screening purpose can be reached.

Specifications

Design/struction/Details Pics

1)Features

- Impact loads are absorbed by pans of rolled alloy/ cast alloy/ manganese steel material depending on application and are similar to heavy-duty track-type undercarriage shoes.

- Pans are bolted to forged link chains supported on heavy-duty lifetime lubricated rollers.

- High strength pans resist abrasion and withstand heavy impact loads.

- Short pitch and precision-machined chain provides noise-free discharge of material with negligible impact on receiver.

- Chain and roller flanges maintain rigid alignment of pans in relation to skirt.

2)Application

- DSMAC Apron Feeders are engineered for heavy-duty operation and for primary or subsequent application stages. Our apron feeder also has an integral matching scraper conveyor with built-in drive to handle spillage.

Parts Details

Drawing

Driving Mode

| Packaging Detail:Standard seaship package |

| Delivery Detail:30 working days |