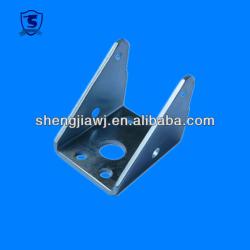

High Precision Iron Stamping Part

| Place of Origin:Guangdong China (Mainland) | Brand Name:SJ | Model Number:iron stamping part | Type:Stamping Parts,Iron stamping part |

| Material:Iron,Steel, stainless steel.iron,aluminum,or as your request | Certification:ISO9001 | Name:High Precision Iron Stamping Part | MOQ:1000pcs |

| Certificate:ISO9001 | Feature:High precision and durable | Processing machine:stamping machines,laser cutting machine, CNC bending.... | Machining accurancy:+/-0.1-0.5mm |

| Thickness of iron stamping part:0.5-6mm | Price:The price of iron stamping part can be negotiable |

Iron Stamping Part

1.material of iron stamping part: Aluminum,red copper,phosphor copper,cold-plate,hot-plate,brass or yellow metal,iron,stainless steel,SPCC,SECC,ect.

2.Surface treatment of iron stamping part: generally finish for iron stamping part is anodizing,other surface treatment is electroplate,electrophoresis,coating or powder spraying,baking finish,brushed,polishing,passivation,silk print,laser,degreasing,etc.

3.Product process of iron stamping part: Progression die, Deep drawing, Grinding, Stretch, Punch, Bending,

Surface treatment and Assembly, QC and shipment.,this is the generally process for iron stamping part,if the iron stamping part is simple,then the process will be simple,while the process of iron stamping part will be complicated,

4.Usage of iron stamping part: gernerally speaking,iron stamping part widely usedin electronic appliances,communication equipment,computer peripheral equipment and other field,that is to say,the iron stamping part has many usage and can be used widely.

5.Payment for iron stamping part:1.Mould Charge 50% of iron stamping partpaid in advance,and the banlance for iron stamping part should be paid after samples confirmed.

2.Production Charge for iron stamping part: 50% of aluminum stamping part should bepaid in advance before mass production, and the balance of iron stamping part should paid before shipment.

6.Advantage of Iron Stamping Part

a.As OEM/ODM,we have specialized in design and manufacture all kinds of iron stamping parts for about ten years,so we have rice experience in design and manufacture iron stamping parts.

b.Buyers' specification of iron stamping partand customized material,size,color,finishing of iron stamping partsare highly welcome.

c.Our iron stamping part has passed ISO9001 and RoHS compliant,it is belongs to environmental-friendly products,we can guarantee it is non-toxic.

d.Proessional engineers,rich experienced QC staffs and good team cooperation could guarantee offer you the best service,we are believe we can offer you the best iron stamping part.

f.Excellent products,reasonable price,accurate delivery and sincere service.

Note: 1.Porfessional working team,modern technology,reasonable price,accurate delivery,sincere service can guarantee to offer you the best iron stamping part.

2.Many kinds of iron stamping part are available,and customized iron stamping part are highly welcome.

3.If you want to know more about our iron stamping part,please view our website.

Pictures of high precision iron stamping part

Workers are producing the high precision iron stamping part

Testing equipment for high precision iron stamping parts

Certificate of high precision iron stamping part

Dispatching area for finished high precision iron stamping part

Specifications:

| We are professional in metal stamping, CNC punching, bending, mold designing with more than 31 years experience. | |||||||

| Item Name | Iron Stamping Part | ||||||

| Material | Stainless steel,brass,copper,aluminum,SPCC,SECC,etc | ||||||

| Processing scope | Stamping, CNC punching, CNC bending, riveting, welding, drilling,etc | ||||||

| Finish | Plating(Zinc,Nikel,Chrome,Tin,Ag),Painting,Powder coating,Anodizing,Sand blasting,etc | ||||||

| Industry | Communication equipment,electric equipment,medical equipment,industry control equipment,security equipment and consumer filed | ||||||

| Certification | ISO9001:2008/ROHS | ||||||

| Production leadtime | 20-30 days after deposit | ||||||

| Terms of payment | T/T,L/C,Western Union(discussible) | ||||||

| Port of loading | Guangzhou/Hong Kong/Shenzhen | ||||||

| Drawings and Samples are Welcome,We also design according to comsumer's description and ideas | |||||||

| Suitable packaging for safe transportation and storage or otherwise specified by customer. | |||||||

| OEM orders are welcome,we can engage in tool designing to volume produce. | |||||||

| Inquiries are typically answered within 24 hours. | |||||||

Comments on metal processing:

1.Material:steel, stainless steel, aluminium, copper.etc.

2.Finish:powder coating, painting, zinc plating, nickle plating, chrome plating,hot-deep galvanizing, cathodeelectro-coating, anode electro-coating,b rushing, sand-spraying;

3.Fabrication machine:laser cutting machine, CNC shearing machine,CNC punching machines, CNC bending machines, stamping machines,etc.

4.Competitiveprice;

5.High quality and fair delivery time;

6.Strict quality controlaccording to ISO 9001:2008

Related products of our iron stamping part

| Packaging Detail:box,carton, poly box or plastic bog or according to your requirement. |

| Delivery Detail:accoring to the quantity of iron stamping part |