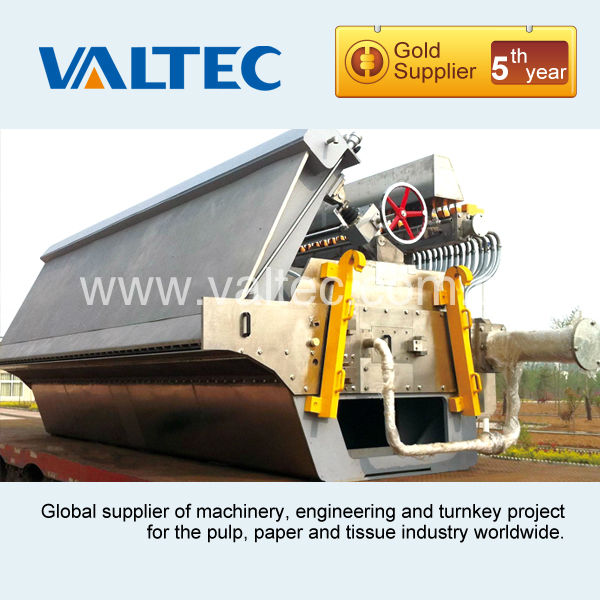

Headbox

| Place of Origin:Shandong China (Mainland) | Brand Name:Valtec | Model Number:VHB-II | Material:SS316L |

Hydraulic Headbox-Main Characteristics

Headbox type : Fully Hydraulic (Option: with dilution water control and with lamella )

Slice design flow : 1600m3/h

Number of lip micro adjustment : 26

Headbox horizontal adjusting range : 0-25mm

Lip opening : 0-70mm

Design return flow rate : 10%

Products: High quality fine paper grade, newsprint, kraft/ liner paper grade, board grade, tissue grade, thin paper grade, etc.

Grammage range: 13-40GSM/ 40-80GSM/ 60-120GSM/ 120-250GSM

Operating speed range: 500-1500MPM

The complete headbox assembly including manifold, mani-tube bank, equalizing chamber, turbulence generator, lamella, slice lip, vertical lip and horizontal lip adjustment mechanism, lip micro adjusting mechanism, edge flow device , headbox control system, positioning device, pressure pulsation attenuator, support stand and walkway.

Hydraulic Headbox Outline Drawing

- Manifold

- Dilution water plate

- Mani-Tube bank

- Equalizing chamber

- Turbulence generator

- Lamella

- Bottom Lip

- Dilution water valve

- Dilution water manifold

- Top lip vertical adjustment mechanism

- Top lip horizontal adjustment mechanism

- Top lip

- Top Slice

Edge Flow Device ( Fibre Orientation)

Fibre orientation is used for describe the extent of fibre deviated the machie.

Adjusted the edge flow to affect the fibre Orientation and make the paper more uniform.

The manual edge flow valve is installed on operating side and driving side each.

Adjusted the edge flow to avoid the stock diffuse to side of the wire.

If the edge flow is under optimal value, stock flows to two sides,(stock wire ratio is higher 1, fibre deviated

to edge, stock wire ratio is lower 1, fibre deviated to centre) If edge flow exceed 1, stock flow deviated to

centre.

Lamella

Lamella is used to ensure the stock in steady and uniform.

The stock turbulence will be more strength.

Dilution water control:

The Seller provides logic description of dilution water control for DCS.

Dilution water control valve connected with the end-user’s DCS system and managed by DCS

system.

Dilution water valve is controlled by QCS which communicate with DCS, the control signal will be

transmitted to dilution water valve via DCS.

The end-user’s QCS system must have the function of dilution control, so thatthe existing QCS

system can be upgraded with dilution water control system.

Schematic picture of dilution water system:

Please provide the following main data of headbox, so that we can make an offer to you accordingly.

| Paper grade | |

| Grammage | g/m2 |

| Main grammage | g/m2 |

| Paper trimmed width | mm |

| Paper width at pope reel | mm |

| Headbox pond width | mm |

| Wire width | mm |

| Sole Plate C-C (Wire Section) | mm |

| Wire height | mm (Height from wire surface to head box sole plate surface) |

| PM operating speed | m/min |

| PM design speed | m/min |

| Raw materials furnish | |

| Retention ratio | % |

| Feeding stock consistency | % |

| Pulp freeness | ° SR |

| CD Shrinkage | % |

| Finished paper dryness | % |

| Machine capacity | ton/day |

| Brest roll size | mm |

| Machine drive side | (When looking from pope reel towards hedbox, the driving side is located at ) |

| CD basis weight variation requirement |

For more details, please contact us

| Packaging Detail:According to export standard, wooden case |

| Delivery Detail:3-6Months |