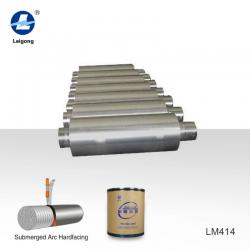

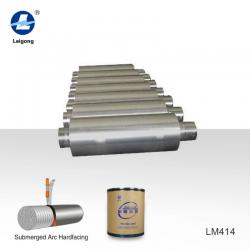

hardfacing hot rolling mill

1. Hardness: 40-50HRC, 2. Metal-to-metal wear, 3. Submerged wire, 4. Corrosion, heat fatigue, oxidation resistance - details see: https://www.machineto.com/hardfacing-hot-rolling-mill-10169610

| Condition:New | Type:Hot Rolling Mill | Place of Origin:Tianjin China (Mainland) | Brand Name:Leigong |

| Model Number:LM 414 | Welding Process:Gas-shielded arc welding wire | Shielding gas:CO2/ 80%Ar+ 20%CO2 | Application:Casting roller, foot roller |

LM414 is used for hardfacing worn roller of hot rolling mill, such continuous casting roller, pinch roller, etc with excellent wear , corrosion, oxidation and heat fatigue resistance.

Chemical Composition(%)

| C | Mn | Si | Cr | Mo | Ni | N | Others | Hardness(HRC) |

| 0.1 | ≤2.0 | ≤1.5 | 13.0 | 4.0 | ≤2.0 | 45~52 |

The hardness is for three-layer deposit about 8mm

Raw material

Our Workshop

Our Lab

Package

Hardfaced continuous casting roller

LM414 is used for hardfacing hot rolling mill roller with excellent properties.

Notes:

- Remove fatigue layer, oil and rust before welding.

- Preheat and keep interpass temperature to 150°c.

- Heat preservation and slowly cool to 100 °c.

- Store wires in dry place with good ventilation.

| Packaging Detail:2.4mm 50kg/coil, 150kg/drum, 250kg/drum 2.8mm 50kg/coil, 150kg/drum, 250kg/drum 3.2mm 50kg/coil, 150kg/drum, 250kg/drum4.0mm 50kg/coil, 150kg/drum, 250kg/drum hardfacing hot rolling mill roller |

| Delivery Detail:15 days |