Grain Steel Silo Price

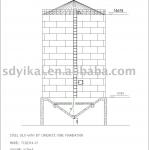

| Condition:New | Capacity:2660m3,2048t | Material:Steel | Place of Origin:Shandong China (Mainland) |

| Brand Name:TSE | Model Number:TCK14613 | Dimension(L*W*H):14.6m*14.6m*18.02m | Weight:29.6t |

| Model:TCK14613 | Diameter:14.668m | Layer:13 | Volume:2660m3 |

| Eave height::14.615m | Total height:18.020m |

Grain Steel Silo Price :

Brief Introduction:

Our company.Taian Shelley Engineering Co., Ltd.,is a professinal supplier in China specialized in producing different storage steel silos. We could design, calculate, install and maintain steel silos according to your different needs. We could manufacture various kinds of steel silos, such as flat bottom steel silo and hopper bottom steel silo, the diameter ranging from 1.8 to 30m, capacities from 5 to 12000 tons per storage bin.

In addition, we could offer our clients material handling system, such as, drying system, cleaning system, bucket elevators, drag conveyors and belt conveyors. One source for all your grain storage, drying, packing, and material handling needs.

Life circle of our products, steel silos, can come up to 20-50 years. Our products are completely comply with the national standards "The Grain Codes of Silo Design" and have reached the advanced national levels in performance.

Our steel silos have been exported to Argentina, Australia, America, China, Ethiopia, Honduras, Iran, India, Korea, Malaysia, Myanmar, Poland, Pakistan, South Africa, Sudan, Serbia, Thailand, Ukraine, Vietnam, etc.

Grain Steel Silo Price :

Taian Shelley Engineering Co., Ltdis a professinal manufacturer in producing grain storage steel silo. Our steel silos are made of hot dip galvanized steel sheets with 275g/m2 galvanized coating. All steel silos are of high efficiency and good quality. The life span could reach 20 to 50 years.

Flat bottomed steel silos are with large diameter and capacity, which is popular for its easy installation and lower costs.

There are many ways for unloading, such as the free-fluidized unloading, multi-spot unloading, the flat bottom sweeping unloading and clean by hands etc... We can also choose the concrete conical bottom to put the automatic-flow unloading into practice.

The flat-bottom steel silos can be widely used in grain process and storage lines, some of them can be chosen to be used in oil, feed, flour, starch, brew, and port or grain storage industrial lines.

We can supply the accessory equipment of the grain steel silos:

*Handling equipment

Elevator

Conveyor

* Pre-cleaner

*Dryer

* Ventilation system

* Dedust system

* Temperature monitoring system

* Moisture monitoring system

We supply steel silo foundation design/ construction, steel silo installation and client can rely on our preferct after-sale service.

Steel Silos :

- Commercial Type (Flat Bottom) Steel Silos with capacity from 100 tone to 10.000 tone

- Conical Type (Hopper Bottom) Steel Silos with capacity from 10 tone to 1.000 tone

Silos includes level sensors,aeration system with centrifugal fan,temperature control system and sweep auger as an option.

CARRYING EQUIPMENTS :

- Bucket Elevator with capacity from 1 tone/hour to 400 tone/hour

- Chain Conveyor with capacity from 1 tone/hour to 400 tone/hour

- Screw Conveyor with capacity from 1 tone/hour to 200 tone/hour

- Elevator Towers

- Electrical and Manuel controlled Slide gates

- Distrubutors with 1 in 2/3/4/5/6 out

- Catwalks

- Spout Pipes

MACHINES :

- Drying Machines ( Tower Type and Horizontal Type ) with capacity from 5 tone/hour to 50 tone/hour

- Mill Machines with capacity from 5 tone/hour to 50 tone/hour

- Pellet Machines with capacity from 5 tone/hour to 50 tone/hour

Advantages:

1. Lower basic cost with lightweight, low request for foundation, low consumption of steel.

2. High degree of standardization. We can produce the standard components which can be installed on-the-spot.

3. Simple, easy and efficient to install within a short amount of time due to superior component design which are connected by standard bolts.

4. Easy to understand. The bolted silo is equipped with relevant accessories, such as: conveyor, ventilation, drying and monitoring devices, etc. to ensure the quality and safety of the material stored in the silo.

5. Easy to maintain. As the parts of the silo are connected by standard bolts, so it is easy to remove or repair it.

6. Low cost and long tenure of use. The cost of bolted silo is just 35%-50% of the cement silo with the same specification; and its life span can reach 30 years.

Installation Of Grain Steel Silo:

The installation of steel silos can be carried out by different ways.

If the client wants to install steel silos by themselves, we could offer detailed instruction, And any question in the process, we'll give our quickest response to deal with the question.

We could also send our engineer to supervise the installation process. The client could find local workers for the installation work. Our engineer will help them during the process.

If the client needs, we could send our installation team for the whole installation issue.

Previous Projects:

Customer From Congo Came to Visit Us In May, 2013

Shelley Engineering Co. Ltd is waiting for your specific inquiry!

We'll give you the best technical support!

Welcome you visit us at any time!

| Packaging Detail:In nude |

| Delivery Detail:1-3month/months |