Good Performance Mining Vibrating Feeder for Ore, Coal

| Condition:New | Application:quarry plant, chemical, steel works,,Steel Plant, Heat Power Station, Chemicals, Mining | Power Type:Electric | Capacity(t/h):accoring to the final design |

| Place of Origin:Henan China (Mainland) | Brand Name:SDZD | Model Number:GZG | Certification:ISO9001:2008, CE,ISO9001:2008 and CE |

| Warranty:18 months | After-sales Service Provided:Engineers available to service machinery overseas | Material:Carbon Steel, Wear/Heat Resistant Steel | Granular Size:Max.400mm |

| Color:Blue,Green, Grey,Red, as request |

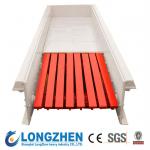

Mining Vibrating Feeder

Introduction and Woking Principle

Vibrating feeder consists of steel frame, spring, hanger and vibrator source.

Once vibrating feeder through the power on, two eccentric blocks on each side of motor shaft will generate a very large exciting force which could be passed to the whole machine. Materials in vibrating feeder will slip and sling on the funnel moving forward.

Application and Feature

Vibrating Feeder is widely used in mining, metallurgy, coal, building materials,light industry, chemicals, agriculture industries for feeding the bulk, granule and powder materials. It can be also applicable for automatic batching and quantitative packing and achieve the automatical production by automatic control.

1.With totally-enclosed structure, it also can be used in poor working environment.

2.Wear reisistant liner be fixed (as customer request) in vibrating feeder box to increase service life.

3.GZG vibrating feeder can be used in the occasion which space is limited.

4. Select high-quality motor and spring, reduce the maintenance cost and the down time.

5.As the materials in the feeder trough are fed up continuously in the process of feeding and jump in the parabolic trajectory , therefore it causes less damage to feeder.

6.It is not suitable for the occasion of explosion-proof requirements.

7.Conditions of the use of electrical control devices:

a.Elevation height is not more than 1000m.

b.The temperature of surrounding medium is less than -20 °C ~ +4 °C.

c.When the temperature of surrounding medium is 25 °C, the relative humidity is not more than 85%.

d.Around there is no medium of serious corrosion and affect electrical insulation properties.

Partial Technical Specification

Our Factory

Our factory has more than 50 years experience in Material HandlingEquipment: vibrating screen,conveyor, feeder, dust collector, vibrator motor, ect. we're 50 year professinoal and recognized expert in this field which can provide you the best technical support. And our company also has passed theISO9001:2008 Quality System Certificate, and obtained theCCC, CE Certificates.

| Packaging Detail:1.wooden case 2.standard packing 3.as need |

| Delivery Detail:15-20 working days after the receipt of advance payment |