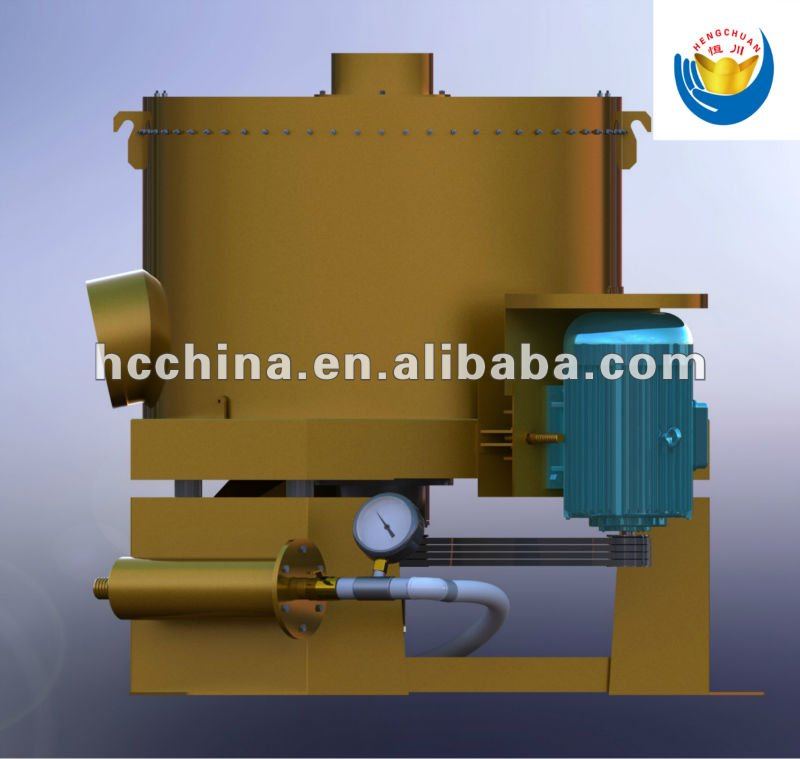

gold centrifuge concentrator for gold recovery Knelson type

| Condition:New | Type:Magnetic Separator,Mineral Processing & Screening Equipment | Place of Origin:Shandong China (Mainland) | Brand Name:HengChuan |

| Model Number:STL | product name:placer gold concentrator | mining object:Metallic and Non-Metallic Ore Excavator | applycation:Iron Ore, Copper, Quartz, Stone, Golden |

| Technology:Centrifugal | color:as request | Models:STL20 STL30 STL60 STL80 STL100 | Ore testing:supply |

| Onsite Installation:supply | main marklet:North America, South America, Eastern Europe, Southeast Asia, Africa |

Gold centrifugal concentrator

Application of gold centrifugal concentrator shows that the Recovery can be as high as 99%, and the upgrade ratio is up to 1, 000 times.

Centrifugal concentrator Feature

1. High concentrating ratio and high recovery

2. Total process automation, steady recovery performance

3. Center discharge design for fast, secure concentrate removal

4. \*+-6/8

5. LQP+*/environmentally friendly(requires no chemical additives or reagents)

6. Low water and electricity requirements

7. Low production costs, durable wear parts, minimal maintenance requirements

8. Compact design requiring less space, easy merged into the existing mining processing

9. Quick payback on investment, typically lass than half year

Centrifugal concentrator Description

Gold centrifugal concentrator was patented in China. It is efficient equipment for recovering free gold in all particle size ranges, especially for recovery of fine gold which is lost during the operation of the gravitational concentrators (sluice boxes and jigs). It can be used not only for placer gold mining, but also for hard rock mining to recover the natural gold, replacing amalgamation, and recover gold from the old tailings.

Application shows that the recovery can be as high as 99%, and the concentrating ratio is up to 1, 000 times. In recovering the natural gold in lode ore with size -0.074mm, the gold is up to 98%, for 0.004mm in particle size, the gold recovery is 97%.

The Gold centrifugal concentrator will separate any heavy material from any light material so long as there is sufficient difference in the densities of the individual particles in question. The gold centrifugal concentrator can treat particle sizes from below 10 microns up to a maximum of 6mm and is most commonly used for recovery in Gold and Platinum. Other recovery uses include Mercury, Palladium, Tantalum, Copper, Silver and Diamond Indicator Minerals.

Rugged design and a high degree of quality manufacturing ensures that every gold centrifugal concentrator will provide many years of reliable, trouble-free operation in even the most severe operating environments.

STL type centrifugal machine is one kind of gold separating equipment,which is specially designed for the recovery of placer gold and lode gold. It is an ideal gold recovery equipment - working on land or in river.

Our company have developed 5 types centrifuge. After test,the placer gold recovery rate is above 99%. For the gold rock mine,when the particle size is under 0.074mm,and the percentage is about 65%,the recovery rate is about 98%;when the material size is about 0.04mm,the recovery rate is about 97%. When the final concentration discharging cycle time is 1-4 hours for gold rock mine,and 4-8 hours for placer gold ore.,the enrichment ratio is about 500-1000 times of raw material.

PRINCIPLE:

Motor(2) drive inner tank(5) rolling at high speed by belt(1) and axis(11). Separation work will be strengthened in the tank(5) by centrifugal force.light material will be discharged by port(7),and final refined ore will be output by port(7) after stopping work.

placer gold concentrator test :

We can produce all kinds of gold mining equipment,such as gold centrifugal concentrator,shaking table ,vibrative sluixe box,amalgamator,and so on ,welcome to visit our factory.

| Packaging Detail:Standard Packing or as Required |

| Delivery Detail:15-30days nafter the 40% deposit |