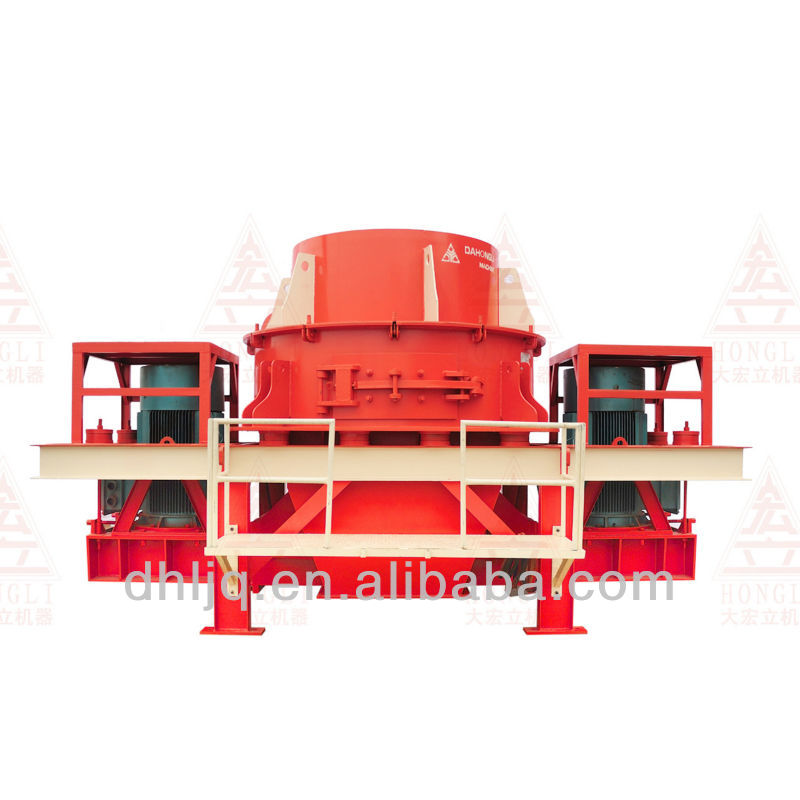

fine impact crusher sand maker PCL500 VSI impact crusher

| Condition:New | Type:Impact Crusher | Application:stone breaker,Limestone, CaCO3, Ore, Concret, Granite and all kinds of Mineral Stone | Motor Type:AC Motor |

| Power(W):2*200KW,2*250KW | Capacity(t/h):140-180,200-250 | Place of Origin:Sichuan China (Mainland) | Brand Name:Dahongli |

| Model Number:PCL500 | Dimension(L*W*H):unsure | Weight:14300KG,15500KG | Certification:ISO9001:2008 |

| Warranty:one year(2000 working hours) | After-sales Service Provided:Engineers available to service machinery overseas | Max Feeding Size:40mm | Discharge Size:1mm |

| Spare Parts:Supply | Installation:Our Engneer On site Installation | Post sale service:For Whole Life | Color:Orange |

Product Introduction:

Dahongli PCL vertical shaft impact crusher is a model integrating advanced mechanism and scientific design and realizes long service life, safe and reliability, large crushing ratio, high sand making rate and high production capacity. It is mainly used in aggregate crushing and shape dressing of construction material. The products have good shape, moderate fineness modulus and low unit consumption.

1. Dilute oil circulating lubrication system: Dahongli PCL vertical shaft impact crusher uses advanced automatic circulation lubrication system. The lubrication is complete. The cooling is faster. It is safe and reliable, without the need of daily maintenance work as required by dry oil lubrication system, greatly increasing its service life and ensuring its normal operation under high temperature, high-dust and high strength conditions.

2. Perfect control system: Dahongli PCL vertical type impact crusher has protective mechanism against overload, over-current and short circuit, and can supervise the oil temperature and backflow volume. If the temperature is too high or the backflow is too small, the system will send out alarm and automatically shut down the crusher, so that it can protect the equipment and ensure safety at the same time.

3. Stone-on-stone chamber and stone self-lining (iron chamber): Dahongli PCL vertical shaft impact crusher yields products with large crushing ratio and sand making rate. It is suitable for material crushing and construction aggregate sizing, with fine shape, moderate fineness modulus and lower equipment abrasion.

4. Other: Dahongli PCL vertical shaft impact crusher can use sand bed or crushing liner as impact wall. Its low abrasion, high productivity, large handling capacity, fine aggregate shape and double-motor (single motor)-driven power system greatly increase operational efficiency of equipment.

Working Principle:

When vertical shaft impact crusher works, aggregates are forced into the crushing chamber at a speed of 40-100m/s under action of centrifugal force. The suspended aggregates collide violently with the liner and move upward along the piling surface and then deflect downward. They crush against the aggregates spurted out by the impeller, lose energy and then discharged from the crushing chamber. Its major functions are impaction and grinding, as well as crushing.

Product Characteristics:

1. Scientific design and advanced oil circulating lubrication system

Oil lubricates the core rotating part making lubrication thorough.

Scientific cooling system ensures normal operation in constant temperature and maintains the best conditions at which the core parts are running thus prolonging its service life.

Scientific heating system ensures the equipment can reach normal working temperature in a low temperature environment.

Scientific protecting mechanism can monitor the service data such as oil temperature and oil pressure in real time.

2. Advanced working principle and high productivity (stone-on-stone principle)

Since stones collide with each other, it does not contact the inner liner, thus reducing wear and maintenance work.

Stone-on-stone working principle ensures large yield of fine aggregates.

The working principle ensures good shaping. The aggregates are cubes with little sharp products.

3. Scientific design and automatic overflow

Scientific overflow design ensures normal operation of motors with stable loads.

Automatic overflow design increases the handling capacity.

Notes of Attention:

1. Feed material should be kept under control, or it will cause damage to vulnerable parts.

2. Avoid too much small aggregate, or it will affect the result of sizing.

3. Avoid too much water content, or it will result in sticky impeller and affect normal operation of the equipment.

4. Maintain smooth discharge.

5. Uniformly feed material, so that fine aggregates and cubic products will be produced.

6. Protective device should be provided against too rigid materials before entering the crushing chamber.

7. The crushable hardness of stone may affect the sizing and fine product content.

8. There should be a balance between the preliminary sieving and closed circuit sieving.

Technical Parameters:

| Model | Max Feeding size (mm) | Motor power (Kw) | Capacity (m³/h) | Material Hardness change | Total weight (including motor) (Kg) |

PCL250 | 40 | 160×1 | 50-70(≤5mm 30%) | 1. hard material (≤5mm30%) 2. medium hard material (≤5mm45%) 3. soft material (≤5mm60%) | 9700 |

| 200×1 | 60-80(≤5mm 30%) | ||||

| 250×1 | 80-100(≤5mm 30%) | 10550 | |||

| 280×1 | 100-130(≤5mm 30%) | ||||

PCL320 | 40 | 160×2 | 90-150(≤5mm 30%) | 16500 | |

| 200×2 | |||||

PCL500 | 40 | 200×2 | 140-180(≤5mm 30%) | 14300 | |

| 250×2 | 200-250(≤5mm 30%) | 15500 |

Dahongli Anywhere:

Thanks to our good quality and post sale service, we have spread our Dahongli Machinery to all over the world

More questions:

If you still have any questions, please feel free to contact with our online service, or our international business department 0086-28-88208058.

| Packaging Detail:Large part is non-packed, small part is in wood case. |

| Delivery Detail:10-30 days |