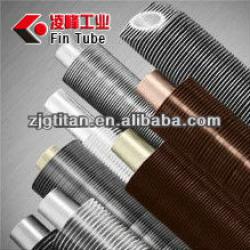

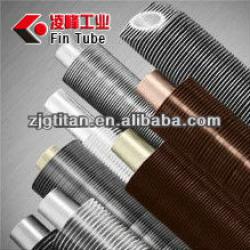

Extruded Bimetallic Finned Tubes

| Place of Origin:Jiangsu China (Mainland) | Type:Refrigeration Compressor | Application:Refrigeration Parts | Fin Thickness:0.25-0.45 mm |

| The fin OD:28 mm - 70mm | Finned Tube OD:25- 88 mm |

The extruded finned tubes are formed in a cold rotary extrusion process, where continuous helical fins are radially extruded from a thick aluminium muff over a liner tube. The process of extrusion hardens the fins and prevents dissimilar metal contacts at the fin root.

The bimetallic tube is consisting of a base tube and an aluminium muff tube. The fins are formed on a cold rolling process from the wall thickness of the aluminium muff tube. A core tube is fitted into an aluminium primary tube. This assembly is then fed into the triple-spindle finning machine.

Three special multi-disc packs extrude the aluminium tube into helical high fins while reducing the inner diameter to give firm pressure contact with the core tube. Extruded fin gives very good corrosion protection to the base tube, as the base tube is not visible to the atmosphere inbetween the fins. Compared to other similar products, our fins do not break, nor do they uncoil, and the lining does not come loose, thereby maintaining the heat exchanger's thermal performance.

Both solid fins and serrated fins can be effected. Extruded Bi-metalic Aluminium finned tubes for construction of heat exchangers for the range of temperatures from 233° To 598° K (-40° To 325° C).

Applications:

Extruded finned tubes are the most sought for various critical Heat Exchange applications as follows:

Aftercoolers, air coolers, air heaters, charge air chillers, condensers, convection heaters, electric heaters, evaporators, fluid coolers, gas coolers, heat pipes, hydrogen coolers, industrial tumble dryers, intercoolers, immersion heaters, oil coolers, radiators, refrigeration, solvent recovery and steam to air heat exchangers.

Fin Materials:

Aluminium or copper.

Bare Tubes Materials:

Bare tubes can be of any material such as brass, cupronickel, carbon steel, stainless steel, titanium, nickel alloy, etc.

FPI: On request.

OD: On request.

Product Range:

Finned Tube OD: 25- 88 mm

Fin Thickness: 0.25-0.45 mm

The fin OD: 28 mm - 70mm.

Advantages:

Uniform and reliable heat transfer. Do not break, unwind or become loose which affects greatly thermal efficiency.

Not mechanically stretched to adhere to the fins

No galvanic corrosion between the tube and fins

Vibration resistant

| Packaging Detail:wooden cases |

| Delivery Detail:30 days |