Environmentally friendly gravity gold centrifugal concentrator with 99% recovery

| Place of Origin:Jiangxi China (Mainland) | Brand Name:GANDONG | Model Number:STLB | Condition:New |

| After-sales Service Provided:Engineers available to service machinery overseas | Capacity:0.5-40t/h | Bowl diameter:200-800mm | Feeding size:-3mm |

| Recovery:80-95% | Appliction:Gold ore | Centrifuge Equipment:Environmentally gold centrifugal concentrator with 99% recovery | ISO 9001:2008 Certification:Approved |

Environmentally friendly gravity gold centrifugal concentrator with 99% recovery

We are professional beneficiation and separating machine manufacturer. Can supply all kind of mining equipments, like Trommel, Sluice, Hopper, Conveyor, Rolling Sieve, Shaking Sieve, Centrifugal Concentrator, Jigging sluice, Gold carpet, etc... Welcome to contact us for more details.

We can make a special mineral processing approach for you with least cost & simplest way.

We can choose the most suitable whole set equipments for your ore.

We can provide you the best price & the best service.

We also provide all small/lab testing mining equipment, welcome to contact me for the details

Smelting furnace please contact me for details

Descriptions

Centrifugal Gold Concentrator is a relatively new type of gravity concentration apparatus. The machines utilize the principles of a centrifuge to enhance the gravitational force experienced by feed particles to effect separation based on particle density. The key components of the unit are a cone shaped "concentrate" bowl, rotated at high speed by an electric motor and a pressurized water jacket encompassing the bowl. Feed material,typically from a ball mill discharge or cyclone underflow bleed, is fed as a slurry toward the center of the bowl from above.The feed slurry contacts the base plate of the vessel and due to its rotation, is thrust outward.The outer extremities of the concentrate bowl house a series of ribs and between each pair of ribs is a groove. During operation the lighter material flows upward over the grooves and heavy mineral particles (usually of economic value) become trapped within them. Pressurized water is injected through a series of tangential water inlets along the perimeter of each groove to maintain a fluidized bed of particles in which heavy mineral particles can be efficiently concentrated.

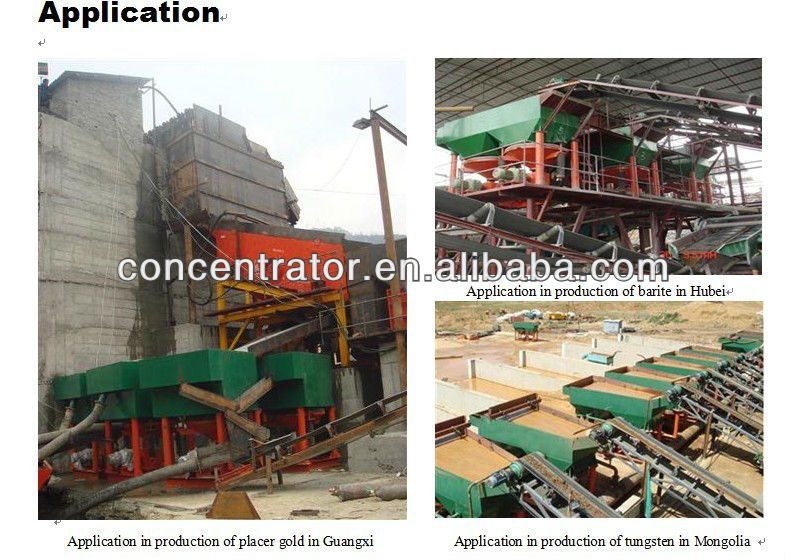

Centrifugal Concentrator was patented in China. It is an efficient equipment for recovering free gold in all particle size ranges,specially for recovery of fine gold which is lost during the operation of the gravitational concentrators(sluice boxes and jigs). It can be used not only for placer gold mining, but also for hard rock mining to recover the natural gold, replacing amalgamation, and recover gold from the old tailings.

Application shows that the recovery can be as high as 99%, and the concentrating ratio is up to 1,000 times. In recovering the natural gold in lode ore with size -0.074mm, the gold is up to 98%, For 0.004mm in particle size, the gold recovery is 97%.

Features

- High concentrating ratio and high recovery;

- Steady recovery performance;

- Center discharge design for fast,secure concentrate removal;

- Environmentally friendly(requires no chemical additives or reagents);

- Low water and electricity requirements;

- Low production costs, durable wear parts, minimal maintenance requirements;

- Compact design requiring less space, easy merged into the existing mining processing;

- Quick payback on investment, typically lass than half year;

Main Technical Parameters

| Model | STLB20 | STLB30 | STLB60 | STLB80 | |

| Capacity (T/h) | 0-0.6 | 2-3 | 8-12 | 40-45 | |

| Fluidization Water Required (m3/h) | 2-3 | 3-5 | 7-10 | 30-36 | |

| Slurry Water Required (m3/h) | 1.5-4 | 5-7 | 8-12 | 40-45 | |

| Feeding Density (%) | 0-50 | 0-50 | 0-50 | 0-50 | |

| Feeding Size (mm) | 0-3 | 0-3 | 0-5 | 0-5 | |

| Concentration Cleaning Up Cycle | Vein gold 1-3 Hours Placer gold:2-6 Hours | ||||

| Concentrate Weight (Kg) | 2 | 3-5 | 10-20 | 40-50 | |

| Power Requirements (Kw) | 0.75 | 1.5 | 4 | 11 | |

| Weight (Kg) | 205 | 380 | 1100 | 2300 | |

| Dimensions (mm) | 914×700×900 | 1160×885×1165 | 1820×1450×1700 | 2520×1900×2020 | |

Note: It is designed according to environmental conditions and customer

requirement set.

The parameters are just for reference. Customized specification is available.

1.About Gandong ---Mining machine

Gandong mining equipment specialized in designing, manufacturing, installing and debugging of mining equipment, providing flow sheet design and course training of beneficiation, the largest manufacturer and supplier of gravity mining equipment in China. 12 years experience, two special factories. Business philosophy "honesty and realistic, quality first, technological innovation", successfully achieved ISO9001:2008 Quality Management System Certificate, meanwhile cooperated with SGS and obtained SGS Audited Supplier Certificate.

2.Intruduction of our gold mining machine

This machine is designed for processing alluvial gold mine, river sand gold, placer gold etc.It is with wheel type chassis, can be driven by vehicles and move easily.

From hopper to trommel exhaust end.

Top: hopper—sluice for discharging stones—trommel— jig—sluice for discharging tailing material

Environmentally friendly gravity gold centrifugal concentrator with 99% recovery

Environmentally friendly gravity gold centrifugal concentrator with 99% recovery

| Packaging Detail:As client request.Environmentally friendly gravity gold centrifugal concentrator with 99% recovery |

| Delivery Detail:20-30days gravity gold centrifugal concentrator with 99% recover |