Energy saving VSI sand making machine price

| Condition:New | Production Capacity:100~130t/h | Place of Origin:Henan China (Mainland) | Brand Name:XBM |

| Model Number:VSI8518 | Voltage:according to your local voltage | Power(W):180kw | Dimension(L*W*H):4140*2280*2425 |

| Weight:14.5t | Certification:ISO, CE | Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas |

| Model:VSI8518 | Throughput capacity (t/h):100~130 | Max. Feed Size (mm):<40 | Rotation speed (r/min):1520~1690 |

| Power of double motor (KW):180 | Overall dimension:4140*2280*2425 | Weight (t):14.5t | VSI sand making machine color:as you wish |

| Installation:we can send engineer | Operation:it's easy |

My friend

Thanks for your support.Trust is the first step of business.We are waitting for your visit during our working time.Please contact us if you have any problems.

(We supply all types of machines as your order)

XBM company

(Xingbang machine)

Specifications

1.Automatic uncovering

2.Big capacity

3.Guarantee 2 years

4.High quality,good price

5.High efficient

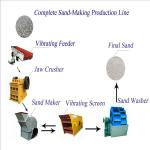

Brief Introduction Of VSI sand making machine

VSI sand making machine is widely used in metal and non-metallic minerals,highways,utilities,refractories,abrasives,glass raw materials,urban construction aggregate,artificial sand and variety of metallurgical slag crushing as also as coarse grinding operation,especially for medium hard, special hard and abrasive materials,such as sillicon carbide ,carborundum,sintered bauxite,magnesite,etc,superiors to other types of crushing machines.Equipped with hydraulic protection jaw crusher,can handle a variety of metallurgical slag.

featuers of VSI sand making machine:

Better quality and high efficiency.

1. Better design of the impellers reduces the resistance of materials, high lightens passing through quantity of materials and crushing ratio, so the efficiency is raised by 30%-60% compared to traditional machines.

2. Hydraulic system allows automatic uncovering, which reduces labor intense and makes maintenance easier.

3. The mainframe adopts new techniques, which strengthens the machine structure and tenacity, and ensures stable performance. The quality of the machines is lift to a higher level.

4. VSI crusher employs world advanced light oil anti leakage device. This saves the trouble of changing oil seal.

Guarantee 2 years, Simple structure ,easy maintanence

Main technical parameters for VSI sand making machine :

Model | VSI7611 | VSI8518 | VSI9526 | VSI1140 | ||

Throughput capacity (t/h) | Center and Ring feeding | 120~180 | 200~260 | 300~380 | 450~520 | |

Center feeding | 60~90 | 100~130 | 150~190 | 225~260 | ||

Max. Feed Size (mm) | Soft material | <35 | <40 | <45 | <50 | |

Hard material | <30 | <35 | <40 | <45 | ||

Rotation speed (r/min) | 1700~1890 | 1520~1690 | 1360~1510 | 1180~1310 | ||

Power of double motor (KW) | 110 | 180 | 264 | 400 | ||

Overall dimension L x W x H (mm) | 3700×2150×2100 | 4140×2280×2425 | 4560×2447×2778 | 5000×2700×3300 | ||

Weight (t) | 11.8 | 14.5 | 17.8 | 25.6 | ||

Power supply | 380v,50Hz | |||||

Lubrication & hydraulic station | Power for double motor | 2 x 0.31 KW | ||||

| Safety | To make sure the supply of oil with double oil pump,working without oil, temperature when water cools, start the motor byheating it in winter. | |||||

| Power for oil box heater | 2 KW | |||||

| Overall dimension L x W x H (mm) | 820 x 520 x 1270 | |||||

Notice: Any change of VSIseries of Vertical Shaft Impact Crusher technical data shall not be advised additionally.

Working principle Of VSI Sand Making Machine

Materials get into machine from feed hopper, which are divided into two parts by distributor. Part of materials by the middle of the distributor get into the impeller of the high-speed rotation, where materials are rapidly accelerated. The acceleration can reach several hundred times gravitational acceleration. Then with the speed of 60-70 m / s , materials are ejected out from the impeller three uniform flow. First be crushed with falling materials around distributor. Then the two parts are impacted onto material lining of vortex cavity, where they are rebound. Materials' oblique impacting on the top of the eddy chamber also changes direction of motion, doing a deflection downward movement. Materials emitted from impeller form a continuous material curtain. So a piece of material in crushing chamber gets twice as well as several times effects of impact, friction, grinding and crushing. Broken materials are discharged from the lower part of the discharge opening. Throughout the crushing process, materials themselves impact and crush mutually. They don't contact metal components directly, and they are crushed because of impact and friction with material lining, which reduces angle pollution and extends the time of mechanical wear.

| Packaging Detail:standard container packing |

| Delivery Detail:about 30 days |