Easy operation BX series drum wood chipping machine

| Knife number(handle):2-3 wood chipping machine | Feed rate (m/min):38 wood chipping machine | Capacity(m3):4-45 wood chipping machine | Power of main motor(kw):45-220 wood chipping machine |

| Weight(ton):2.9-11.2 wood chipping machine | Final product length(mm):25-38 wood chipping machine | Condition:new wood chipping machine | Brand name:LEABON wood chipping machine |

| Raw material:wood branch, wood log, wood waste etc. | Payment terms:L/C,T/T,Western Union |

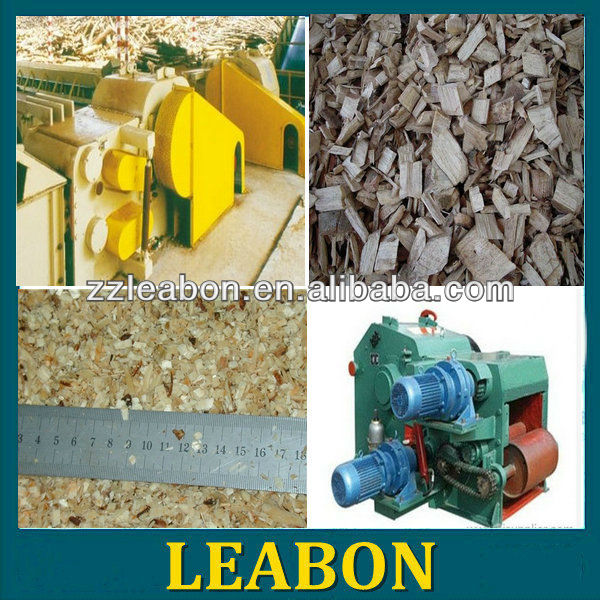

Wood Chipping Machine

1. The Introduction of Wood chipping machine :

The wood chipping machine can cut wood logs, small dimension wood and brushwood under the diameter of 200mm. It can be applied into pulp mill, trees, paper mill, wood factory etc. wood chipper is mainly formed by the host, coupling and chassis, motor parts, including cutting machine, cutter host by trim, feeding and discharging port, etc.

2. The Usage of Wood chipping machine:

This kind of wood chipping machine is mainly used to chip the small diamater wood, wood cutting remains (wood branching tree stumps, branches, etc.) and wood processing of raw material (slab, lath, logs core, waste veneer, etc) and it also can be used to cut non-wood materials (such as sugarcane dry, reed, bamboo, etc.)

3.The advantages of the wood chipping machine

(1). Drum type wood chipping machinealso called the drum chipper, drum chips machine. They are the most popular chips machine for dealing with the wood logs, slim lumber, wood waste, branches, bamboo etc.

(2).The chips from this wood chipping machine can be used in pulp and paper making plant, particleboard plant, wood pellets making plant and so on. And they are also the ideal and direct fuel for the boilers or the biomass boilers.

(3). Thewood chippping machinecan always works together with belt conveyors for feeding and out feeding, so it is easy to achieve the Automation. Besides this, Operation easy, maintenances simple, life long and the noise is low. But output is much higher than the ordinary ones. So they would be the best choice for getting wood chips.

(4). We choose these Wood chipping machinefrom hundred of manufacturers in China mainland. The price is very good and the quality is very high, as we have exported them for many areas all over the world.

4. Main data of the Wood Chipping Machine:

| Model | BX-215 | BX-216 | BX-218 | BX-2113 |

| Knife roller diamete(mm) | 500 | 650 | 800 | 1300 |

| Knife number(handle) | 2 | 2 | 2 | 3 |

| Feed-in material door size(mm) | 180*400 | 240*540 | 310*680 | 450*700 |

Rotational velocity of Knife rotor(r/min) | 592 | 590 | 650 | 500 |

| Feed rate (m/min) | 38 | 38 | 35/37.38 | 38 |

| The diameter of raw material(mm) | 160 | 200 | 300 | 450 |

| Final product’s length(mm) | 25-35 | 35 | 15-35 | 38 |

| Capacity(m3) | 4-5 | 8-12 | 15-35 | 35-45 |

| Power of main motor(kw) | 45 | 55 | 110 | 220 |

| Feeding-in material roller motor power(kw) | 2.2 x 2 | 3 × 4 4 × 1 | 4 x 2 | 7.5 x 2 |

| Weight(ton) | 2.9 | 4 | 7 | 11.2 |

| Outside diameter(mm) | 1540 X1240 X 1020 | 1980 X 1950 X 1250 | 2670 x 2150 x 1500 | 3670×2448× 2050 |

5.Main parts introduction of Wood Chipping Machine

1.This Wood chipping machine cut piece by the body's machine, knife roller,

fluctuation, feed roller, conveyor belt, hydraulic pressure system components.

2. The Wood chipping machine adopts high strength steel welding and into,

is the whole machine of supporting the foundation. Knife roller are installed on

the two or three, four fly knife, use special manufacture of fly knife, through the

pressure of bolt, fly knife fixed in the knife roller.

3.According to the thickness of the different raw materials by cutting, feeding roller

assembly can use hydraulic system in a certain range to fluctuate.

6.Raw materials - Final product

7.Photos of Delivering the Wood Chipping Machine:

| Packaging Detail:International standard package |

| Delivery Detail:within 15 days after receipt payment |