Dust collector /Pulse bag filter/ash collector for aac block

| Condition:New | Place of Origin:Henan China (Mainland) | Brand Name:Huayi | Model Number:as your need |

| Weight:670kg,810kg,1060kg | Certification:ISO | Warranty:one year |

This machine has a feature of simple construction, easy maintenance, long service life, little location, etc. It is widely used in chemical, metallurgy, construction, mining and machinery industries. The removal efficiency can reach to 93%.

Main Technical Parameters:

| Model | (%) Dust Removal Efficiency | (m³) Processing Amount of Wind | (kw) Motor Power | (kg) Weight |

| LX40 | >90 | 4000 | 4 | 670 |

| LX60 | >90 | 5000 | 5.5 | 810 |

| LX80 | >90 | 6000 | 11 | 1060 |

Characteristics:

*Easy install, auto pulse cleaning

*Reliable filter, low noise

*High effeciency, low energy consumption

Performance Features:

1.

2. The casing uses framework structure with high intensity and good stability, it can be designed according to different pressure and temperature resistant requirements.

3. Gas inlet & outlet type can be designed into various kinds of forms according to technical arrangement and flue gas characteristics, the technical arrangement is flexible and changeable.

4. It uses flow resistance plus flow guidance type gas flow distribution equipment, therefore it has good gas flow evenness without dust blockage.

5. The discharge electrode is properly connected with the frame without wire dropping and breakage.

6. It uses hammer type rapping with lateral arm, the rapping strength transmission is even with good effect, therefore, it is easy to clean the dust.

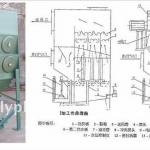

Structures:

Coarse particles directly fall into the ash bucket bottom for wind speed reducing and the ash

bucket spoiler role in the collision, fine dust rose with the bag at all between the fine dust was

blocked leaving the outer surface of the bag, cleaning gas clearance role with negative pressure

ventilation through the bag into the mains from the body into the atmosphere, reaching the

purpose of purification.

Working Principle:

1. The dust-laden air enters the bag filter.

2. The dust /powder separates inside the bag filter chamber.

3. The air is uniformly distributed avoiding channelling while the powder is separated.

4. Initially a coat of material forms on the bags. Subsequently, the coat acts as the filtering medium.

5. The dust is accumulated on filter elements while the air passes through the filter bags fromoutside to inside.

6. The accumulated powder is dislodged from the bags by reverse pulsejet air intermittently.

7. The dislodged powder falls on bottom cone and is discharged through powder discharge valves.

8. The dust free air is sucked by induced draft fan and is exhausted to atmosphere.

| Packaging Detail:container |

| Delivery Detail:15 to 45 days after you order |