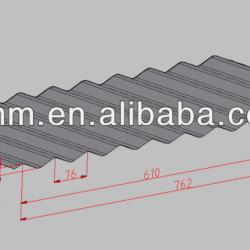

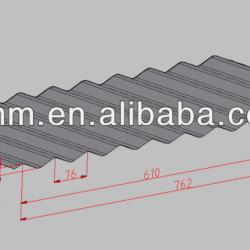

corrugated sheet roll forming machine

| Condition:New | Type:Cold Rolling Mill | Place of Origin:Henan China (Mainland) | Brand Name:Tianfeng |

| After-sales Service Provided:Overseas third-party support available |

TECHNICAL SCHEME 2

- NAME OF GOODS:TF corrugated single deck roll former

- MATERIAL:

(1) Coil Width: 925mm

(2) Suitable Coil Thickness: 0.3-0.6mm(according to your requirement

(3) Suitable Raw Materials:galvanized steel coil, pre-painted steel coil

(4)Yield Strength: 550Mpa

(5)Roll Forming Step: about 16 steps

(6)Material of Roller: 45#, with hard chrome on the surface

(7)Voltage: 380V/50HZ

(8)Line Speed: about 15m/min

- MACHINE COMPONENTS:

(1)Hydraulic un-coiler 1 set

(2) Roll-Forming M/C 1 set

(3) Hydraulic Cutting 1 set

(4) PLC Control System 1 set

(5)Run-out Table(un-powered) 1 set

(6)Hydraulic Station 1 set

(7)Safety Barrier System 1 set

Line working process display:

- TECHNICAL SPECIFICATION

(1) Hydraulic un-coiler

To support and expand the coil.

Motor reducer drives it to uncoil.

Hydraulic system to expand coil innerhole.

Frequency Inverter to regulate turning speed,

Photoelectric switch controls the coil location.

The suitable coil width: 1000mm

Automatic stop device;Load capacity = Max.5Ton.

The expand and shrink range is 480-520mm.

(2) Roll-Forming M/C:

About 16 steps to form

Material of Roller:45#, With hard chrome on surface , polishing.

Voltage:380V/50Hz Line speed:15m/min;

Welded steel plate machine base. Chain and gear move the line, motordrive.

(3) Hydraulic Cutting:

Stop to cut, Post cut; Cutting tool material:Cr12, cutting length tolerance ±2mm;

Hydraulic motor drives.

(4)PLC Control System:

It useSiemensPLCsystem to control the whole line. It can measure and cut the length automatically. Frequency adjusts the speed and it has the self-control speed function.

Human-machine screen, touch screen control. The length can be set in touch screen freely and operation is simple.

The surround connecting wires adopts aviation socket or fast-speed plug.

(5)Run-out Table(un-powered):

Two parts, total length is 6 meters. In order tocollect thefinalproduct.

It can be disassembly and convenient for workers to stack.

(6)Hydraulic Station:

To supply the power for the hydraulic cutter.

(7)Safety barrier system:

In order to protect the workers safe, the simple safety barrier will be covered on the related parts.

| Packaging Detail:wooden box and waterproof cloth |

| Delivery Detail:70-90 days |