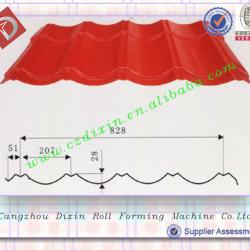

CNC Color Steel Circular Arc Galzed Tile cold Roll Forming Machine Roll Formers

| Condition:New | Type:Tile Forming Machine | Tile Type:Glazed Steel | Use:galzed steel tile |

| Production Capacity:8-10m/min | Place of Origin:Hebei China (Mainland) | Brand Name:DIXIN | Model Number:828/1035 |

| Power(W):4KW | Voltage:380V | Dimension(L*W*H):7800mm*1300mm*1350mm | Weight:5ton |

| Certification:Quality cerecification as the government | Warranty:12 month | After-sales Service Provided:Engineers available to service machinery overseas | Effective Width:828mm |

| Feeding Width:1000mm | material:color steel sheet, galvanized steel sheet, aluminium sheet | hydraulic oil:40# | thickness of material:0.3mm-0.7mm |

| processing speed:0-12m/min | roller station:9rollers |

Color Steel Circular Arc Galzed Tile Roll Forming Machine

Roll speed:8-12m/min

welded by 300H steel

automaticity with PLC control system

always have stock

customized as your requirement

our product have best quality and comptitive price .It has accurate measurement and easy operating .We can design and manufacture the special product according the cuatomers' requirement.

we could provide technical guiding, production, installation, debugging and maintenance service to all customers.

The machine consist of uncoiler and its base, coil sheet guiding equipment, roll forming system, post cutting equipment, hydraulic station, controlling system, supporter table.

1.Machine Parmeter :

| Suitable material | Color steel sheet , galvanized steel sheet,aluminum sheet |

| Machine Sizes | 7800mm×1300mm×1350mm |

| Main motor power | 4KW with Cycloidal reducer |

| Hydraulic station power | 3KW |

| Hydraulic oil | 40# |

| Thickness of material | 0.3mm~0.7mm |

| Diameter of principal axis | Φ76mm |

| Material expand width | 1000mm-1250mm |

| Electric tension | 380V 3phase 50HZ or as the customer's requirements |

| Material of roller | High grade 45# forged steel plated with hard chrome plating |

| Rolling galvanization thickness | 0.05mm |

| Processing speed | 0-12m/min |

| Processing precision within | 10m+/-1.00mm |

| Material of cutting blade | Cr12 mould steel with quenched treatment |

| Kind of drive | 1 inch chain link bearing model 6210 |

| Roller station | 9-13 Rollers |

2. Computer System

| PLC System | “Mitsubishi” |

| Encoder | “REP” |

| Switch | CHNT |

| Transducer | "SAJ"or "OMR |

3.The production process:

4. About us

Our company is a professional roll forming machine manufacturer that has the series of colored steel formingmachines,including molding machine,roof sheet machine,bending machine,C&Z&U shaped purlin forming machine and so on.

5.Equipment maintenance

maintenance of roof panel roll forming machine is quite easy. We recommend that you regularly feed lubricant to the machine gear, chain and moving parts to reduce friction and avoid rusting. Make sure the power lines are properly connected before starting the machine, and at regular intervals, change the gear oil and hydraulic oil.

6. Service

we provide a one year warranty and lifelong technical support will be provided

we can send our technicians to you to give you on-site training. The training period would be for no more than one week with the customer paying for the visa, return ticket, food, accommodations and a daily wage of US50

THE END

there are some other product for your reference.

2-4m hydraulic plate shearing machine

5ton hydraulic material staking machine

Hydraulic bending machine

If you have demand or question ,Please contact us as soon as possible.

Welcome you to our factory!

We have great interest in doing business with you .

| Packaging Detail:main machine is nude and the computer control box is paked by wooden carton box |

| Delivery Detail:30 days after receivede your advance payment |