Charcoal ball press machine/coal ball press machine

| Place of Origin:Henan China (Mainland) | Brand Name:YongHua | Model Number:YHQ Series | Condition:New |

| After-sales Service Provided:Engineers available to service machinery overseas | Reducer:ZQ Series | Main market:South Korea | Capacity:3-5t/h |

| Dimension:As the Customer's Requirement | Color:As the Customer's Request | Installation:Directed by Our Engineer |

Ball press machine for charcoal, coal, dry powder

introduction of Ball Press Machine:

The series of hydraulic ball press machines are a equipment which will press charcoal,coal,dry powder into the ball,which are extensively used in making the following materials briquette, granulate or press ball, such as aluminum scrap, activated carbon, alumina, bauxite, caustic soda, charcoal, clay, coke dust, coal, cryolite, fertilizer, plastics, limestone, pigment, urea.

feature of Ball Press Machine:

1.The goal of machine is to reduce dust, control unit weight, return to use, improve transport properties, etc,and they are widely used in suppressing difficult molding powdery materials, which is characterized by the molding pressure.

2.The main engine revolutions adjustable, equipped with a helical feeding device,double roller with four time pressure,also because high performance of the propelling device, the finished briquettes have lots of advantages such as good density, high hardness and high strength.

technical parameter of Ball Press Machine:

Model | LYQ0.5 | LYQ1.0 | LYQ1.5 | LYQ2.0 | |

Diameter of roller(mm) | 299 | 367 | 367 | 399.5 | |

Width of roller(mm) | 180 | 183 | 183 | 252 | |

Production design(kg/h) | 500 | 1000 | 1500 | 2000 | |

Main motor | Model | YCT250-4A 18.5kw | YCT315-4AB 37kw | YCT315-4A 45kw | BY615-413 45kw |

| Power | |||||

| Hydraulic motor | Model | YCT200-4B 7.5kw | YCT225-4A 11kw | YCT225-4A 15kw | YCT225-4A 15kw |

working principle of Ball Press Machine:

1.Passive roller of ball press machine is braced by hydraulic cylinder piston, the hydraulic circuit,the hydraulic control valve and accumulator ensure system pressure.

2.Quantitative equipment of the storage bin tranfers raw material evenly into the hopper of the molding machine, so the raw material is evenly entered into the middle of the roll, forming pressure from reverse operation on the roller to compress material from small to big.

3.At the centerline of molding, when the pressure will reach its maximum and raw material through the line, molding pressure rapidly becomes smaller in order to make the finished products off the ball smoothly.

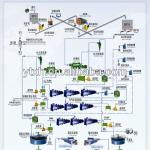

Whole production line:

Different finished products shape:

Other related machines:

Main foreign markets:

The type of ball press machines are mainly exported to all over the world ,such as: India, Indonesia, Kazakhstan, Vietnam, NorthKorea, Egypt, Japan and other places around the world, which is also the ideal equipment for production of formed coal and ball press of powdered ore at home and abroad.

Company Service and Profile:

Pre-sale services:

According to your special needs,design and manufacture products for you,provide you with project design, process design, purchase program suitabled for your machines and equipment.

Sale of services:

Assist you to complete acceptance of the equipment, and the construction program and detailed process.

After sale service:

The company sent technicians to teach how to install the equipment,commissioning and training of operators.

Product quality:

All goods are guaranteed for one year expect for wearing parts.

Note:

We can design every kind of ball press machines according to your special requirement, if you didn't find the satisfactory machine in our company,please don't hesitate to email or contact me immediately.My telephone Number is +86 13663003506.

I will try my best to help you.

| Packaging Detail:Wooden case or as per your special requirement |

| Delivery Detail:Within 20 days after the receipt of 20% deposit |