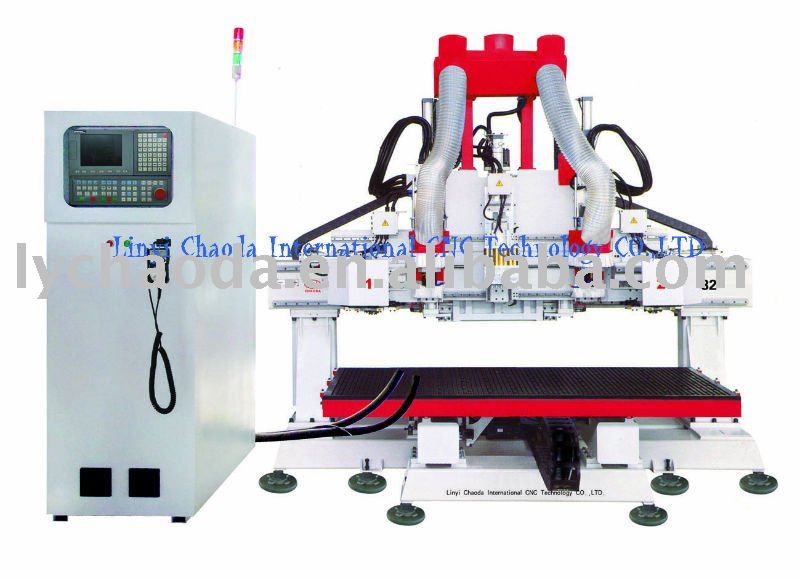

CHAOCDA JCT1632R-2H CNC Wood Carving Machine with Double Disk type ATC system

| Condition:New | Place of Origin:Shandong China (Mainland) | Brand Name:CHAODA | Model Number:JCT1632R-2H |

| Application:CNC Wood Carving Machine | Tool magazine:Double Disk type ATC system, with 16 pcs tool magazine | Moving Mode:Table Movement | Spindle type:Italy 9kw Air cooling spindle |

| Motor:Servo motor | Control system:Taiwan SYNTEC control system | Software:Artcam | Certification:CE and ISO |

| Precision:High Precision |

CNC Wood Carving Machine

Technical Features:

- This Item with Pneumatic Line Boring Head and Saw Blade Unit, it is very suitable for complex and multi-direction works, widely used for engraving , drilling holes, cutting , side milling, cutting edges, 2D works, 3D works, hollow cutting and so on.

- It has double table surface, double spindles, and double too magazines, it is heavy structure design and the table is horizontal .

- The dual heads could process together or respectively, and they can also change at any time, which save the time of changing tools, upgrade the efficiency, improve the randomness of the processing of the machine .

- This machine adpts the best components in the world ,such as German vacuum fsystem, Japan Servo drive system, Italian HSD electospindle and so on.

- Diversified control processing speed can control the working speed , travlling speed, dropping- tool speed, lowering too speed, greatly improve the quality and efficiency.

Applications :

Funiture, audio box, decoration of car and yacht, isolation material in high speed railway’s electric control parts and generator, filter sheet for lithification and paper manufacturing , machine’s material for producing semiconductor and PCB, ceramic chip, panel’s back light module, compact grade and artificial stone for kitchen cabinet, acrylic sheet, display rack ,cooper, aluminum sheet , Pane furniture industry, solid wood doors, office furniture, cabinet doors, wooden sound box, computer table, sports equipment, the engraving of the violin, PVC, Polyethylene, organic glass, plastic and so on.

Technical parameters:

| Description | Parameters |

| Model | JCT1632R-2H |

| X,Y,Z axis working area | 1600*3200*300mm |

| Whole structure | Welded Steel gantry structure |

| Moving Mode | Table Movement |

| X,Y structure | Rack and pinion transmission,high speed and more stable; Y -double motor drive |

| Z structure | Imported ball screw, high precision |

| Tool magazine | Double Disk type ATC system, with 16 pcs tool magazine |

| Max. moving speed | 0-60m/min |

| Max. working speed | 0-30m/min |

| Repositioning Accuracy | ±0.05mm |

| X Y Z working Accuracy | < 0.02mm |

| Spindle | 9kw imported Italy HSD ISO30 air-cooled ATC spindle (option: 5.5kw water-cooled spindle; Italy HSKF63 or HSK F 69 ) |

| Spindle rotating speed | 0-24000rpm/min |

| With Boring head Units Circular Saw Blade Unit | 9 (2x7) Vertical Drills Unit + 1 Bi-directional X-axis Drill Unit + 1 Bi-directional Y-axis Drill Unit + One X-direction Circular Saw Blade Unit (option) |

| Diameter of tools | Φ3.175-Φ20 |

| Collet size | ER 32 |

| Operation language | G code (plt, mmg, uoo, bmp) |

| Inverter | Taiwan Delta inverter |

| Driving system | Servo motor and driver |

| Operating system | Taiwan SYNTEC control system (Option: Taiwan LNC system) |

| Software | UcancamV8 / Type3 / Artcam software (option) |

| Work voltage | AC380V, 3-phase, 50-60Hz |

| Running environment | Temperature: 0°C-45°C; Relative humidity:30%-75% |

| Vacuum pump | German Becker Vacuum pump (option : China-made Vacuum pump) |

| Dust collector system | YES |

| Air Compressor | YES |

| Tool Sensor | YES |

| Auto-Lubrication system | YES |

| Weight | 2300kg |

| Packaging Detail:Steel support and plywood packing |

| Delivery Detail:10 days after confirming the order and payment |