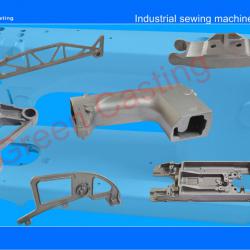

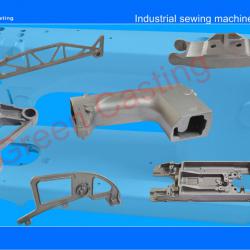

casting for Industrial sewing machine

| Place of Origin:Hebei China (Mainland) | Brand Name:GCT | Machine Type:Sewing Machine | Type:Frame |

| Use:Industrial | Material:grey iron,gray iron,ductile iron, cast iron |

Key words I: casting, foundry, cast iron, casting iron, iron casting, green casting, GCT. Hengshui, Taocheng,

Key words II: gray cast iron, grey cast iron, gray iron, grey iron,

Key words III: ductile cast iron;ductile iron,ductile cast iron, nodular cast iron, spheroidal graphite iron, spherulitic graphite cast iron, SG iron.

Key words IV: green sand casting, green sand process, Toyku, Disa, automatic molding machine. Erich, OBLF, CMM, CNC

Key words V: automobile, crankshaft house, flywheel, wheel hub, clutch pressure plate, belt pulley, brake calipers, carrier, rotor.

Key words VI:High-speed railway parts WJ-7 and WJ8c railroad tie plate, GRTSII Type slab ballastless track slack adjuster, and embedded iron seat, spring rod.

Key words VII: industrial sewing machine parts, bottom plate, sewing machine body, brackets, Beam steering,

Key words VIII: reducer cabinet, housing, pipefitting,trunnion, agricultural machinery, hydraulic pressure, valve, endcover, electric power fitting, iron cap,flange,

What is casting

Casting is a manufacturing process by which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods.Casting isa 6000 year old process. The oldest surviving casting is a copper frog from 3200 BC.

Cast iron,casting iron or iron castingis iron or a ferrous alloy which has been heated until it liquefies, and is then poured into a mould to solidify. It is usually made from pig iron. Usually we use grey iron and ductile iron in mass production.

Casting manufacturing process flow

Thetypical casting manufacturing process flow is consisted ofMelting, Molding, Pouring, Cooling, Shaking-out and Finishing.The follow chart showed us the green sand process with automatic molding line to produce cast iron casting.

1,Products analysis.

2,Pattern making and preparation

3,Melting

4,Core making

5,Sand treatment

6,Molding

7,Pouring

8,Cooling & shaking out

9,Gate and riser removal

10, Grinding and shot blasting

11, Checking and inspecting

12, Machining

13, Packing and storing in warhouse

About Green Casting

Hengshui Green Casting Technology Co., Ltd (GCT)is located in Hengshui of China. We specialized in various kinds ofGray Cast Iron, Ductile Cast Iron, Railway Fastening System, etc., which have been exported toEurope, North America, Japan, and other international market with good reputation.

Forover seven years, GCT has been delivering high quality castings to its customers with the industry’s shortest lead times. We have refined the casting process to eliminate the waste caused by excessive in-process inventory, resulting in a standard process cycle and a quality feedback loop so short that quality problems are solved before they can impact delivery or product cost.

Green Casting

Won high quality casting gold awards in 2009/2010 Chinacastpartexhibitions.

Pacesetter enterprise of The 1’st National Foundry Industry of CFA

We can serve you as follows

Casting

castings in material of ductile iron and grey iron with automatic molding line;

Machining service

Machining work with CNC

Rubber

Engineering rubber products with advanced rubber processing line

Rail fastener

Spring rod for rail with automatic spring rod producing line

Data GCT

| Description | Data |

| Registered capital | CNY150 millions/USD25millions |

| Covering area | 233 thousand square meters |

| Building area | 120 thousand square meters. |

| Total assets | CNY 738millions/USD123millions |

| Fixed capital | CNY276 millions/USD45millions |

| Sales income | CNY604 millions/USD100millions |

| Total staffs | 350 |

| Annual capacity of castings | 50000MT |

Company Basic Information

Company Name: Hengshui Green Casting Technology Co., Ltd

Year Established: 2005

Business Type: Manufacturer,

Main Products: castings in material of gray iron and ductile iron, Railway Fastening System,

Operational Address: Green Technical Park, Taocheng District, Hengshui, Hebei, P.R. China

Number of Employee: 300-400

No. of R&D Staff: 20-30

No. of QC Staff: 10-20

Management Certification: ISO9001:2008, ISO/TS16949:2009

Contract Manufacturing: OEM Service Offered, Design Service Offered, Manufacturing as customers’ drawing, samples,3D model.

Company Authentication

Registered Address: Tanjiazhuang, Tao-cheng District, Hengshui, Hebei, P.R. China, 053000

Legal Representative: Zhang Keqiang

Legal Form: Limited Liability Company

Registration Number: 131100000019812

Issuing Authority: Hengshui Administration for Industry &Commerce

Date of Issue: August 3, 2005

Date of Expiry: August 2, 2015

Registered Capital: CNY 150 000 000

Trade Capacity

Trade & Market

Main Markets: North America, Eastern Asia, Western Europe, Domestic.

Total Annual Sales Volume: CNY 604 000 000

Export Percentage: Direct 40%, Indirect >90%

Trade Ability

Language Spoken: English, Chinese,

Export Mode: Self-Run Export

Export License Number: 1311960509

Business Terms

Accepted Delivery Terms: FOB, CIF, CFR

Accepted Payment Type: L/C, T/T,D/P,D/A,CAD

Nearest Port: Tianjin Xingang, Qingdao, Shanghai, Beijing airport.

Production Capacity

Factory Information

Factory Size: 23 3333 square meters

Factory Location: Green Technical Park, Tao-cheng District, Hengshui, Hebei, P.R.China

Production Lines: 2 X Toyku AMF-III07R Horizontal Molding Line

1 X DISA131 Vertical Molding Line

4 X Railway Fastening System Production Line

Contract Manufacturing: OEM Service Offered, Design Service Offered, Casting manufacturing as customers’ drawing, samples, 3D model.

Production Capacity

Railway Fastener: 48 000 tons/year

Casting: 50 000 tons/year

| Packaging Detail:wooden cases,iron cases |

| Delivery Detail:4-8weeks |