5L~3000L emusifying cosmetic machine vacuum emulsifying mixer machine

| Condition:New | Mixer Type:Homogenizer | Product Type:Cosmetic | Application:Liquid with Suspended Solids |

| Additional Capabilities:Granulating | Place of Origin:Guangdong China (Mainland) | Brand Name:Promake | Model Number:PMK |

| Max. Loading Capacity:it depends | Voltage:220V/380V | Power(W):it depends | Dimension(L*W*H):it depends |

| Certification:CE ISO | Warranty:12 months | usage:emulsifying mixer for cosmetics | material:stainless steel |

| MOQ:1 set | heating:steam heating or electric heating | homogenizer:upper or bottom |

5L~3000L emusifying cosmetic machine vacuum emulsifying mixer machine

PMK Emulsifier industrial cosmetic mixer equipment We can supply four series of the vacuum

emulsifying mixer they are PMK-A, PMK-B,PMK-C,PMK-D

The vacuum emulsifying mixer is mainly composed of water pot, oil pot, emulsifyin pot, vacuum system lifting system (optional), electric control system (PLC is optional), operation platform.

Detail info:

1. PMK-A Series

This series machine is designed for small and medium scale cosmetic factory and pharmaceutical

factory. It is economical type mixer. The biggest feature is homogenizer on the bottom, more powerful

very suitable for high viscosity materials. Hydraulic system, tilt system .All contact material part

adopts SUS316L, polishing reach 300 mesh

PMK-B Series

This series machine is designed on the basis of U.S.ROSS company technology .

it is suitable for the production of foundation, paste & cream, toothpaste etc.

The feature is:It can realize second time emulsifying, very suitable for high capacity

of high viscosity material .Homogenizing more thoroughly than other model mixers.

PMK-C Series

This unit adopts top coaxial triplet blender, hydraulic raise-fall cover, homogenizer speed is 0-3500r/min, rotate speed of low-speed wall scrapping blender is 0-63 r/min (frequency controlled ), homogenizer adopt high speed, high homogenizer eddy emulsifying blender, low-speed wall-scrapping blender stick to boiler bottom and boiler wall automatically, it adopts vacuum suction and

especially vacuum suction to powder material to avoid powder flying everywhere. The whole working

procedure is processing under vacuum condition to avoid material producing air bubble after high

speed blending which can reach sanitation asepsis requirement.

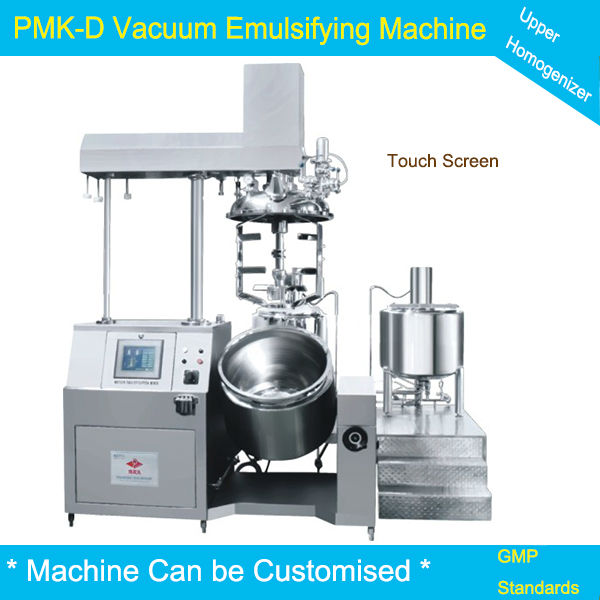

PMK-D Series

This series machine adopts advanced overseas technology, it is designed for big scale

cosmetic factory which manufacture high quality products .The whole system consists of

water pot, oil pot, emulsifying pot, vacuum pump, hydraulic system, discharging system,

electronic control system, work platform and etc. It is suitable for production of various of

paste cream products in cosmetic factory and pharmaceutical factory .Emulsifying effect

is especially effective to material which has big substrate viscosity and high solid material content.

PMK Fixed Vacuum Emulsifying Machine

Small vacuum homogenizing & emulsifying for lab-use machine

This series machine brings in foreign advanced technology and is exclusively designed

according to cream-producing processing of cosmetic and cream production. This machine is composed of

water phase boiler oil phase boiler emulsifying boiler vacuum pump hydraulic system

dropping material system equipment control system work platform and etc

Certificate

The Equipments Promake can manufacture

1) Vacuum homogenizer Emulsifying mixer

2) Liquid washing homogenizing mixer

3) Water treatment equipment (RO system)

4) Filling machines

5) Perfume maker

6) Anti-corrosion equipment and inkjet printer

7) Liquid filling and screw-cap sealing machines

8) storage Tanks

9) Laboratory equipment

10) Filter equipment

About Promake Machine Equipment Co., ltd

Guangzhou Promake Machinery Equipment Co., Ltd. is a professional manufacturer producing daily-use chemicals, medicine machinery and pure water machinery equipment.

We undertake equipment design, manufacture, installation, maintenance, technical improvement support, technical consultancy and other services.

We create value for customers. We not only provide installation service, but also help customers design and select equipment according to existing sites. After-sales department specifically organizes clients to carry out debugging.

The after-sales hotline is open the whole day and willing to provide consulting service for you. We value the good relationships with customers.

MOQ:1 Set

Delivery Time:25 working days after deposit

Payment:T/T, Western Union, Paypal, LC are welcome. 30% for deposit, 70% before shippment.

Chat with us directly viaSkype: martin0gongfor more info are welcome, we are glad to be of help.

| Packaging Detail:plywood case |

| Delivery Detail:30~35 working days |