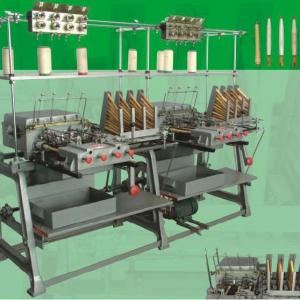

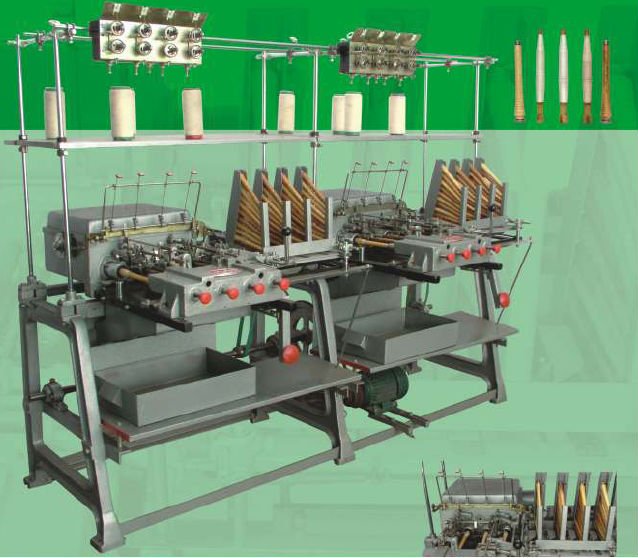

2013 latest best Pirn Winder Machine

Automatic Pirn Winder Machine to Wind Cotton Yarn, Polyester Yarn, Woolen Yarn, Comes in bunch with 4 Spindle., MOQ: 1 piece - details see: https://www.machineto.com/2013-latest-best-pirn-winder-machine-10276555

| Place of Origin:Gujarat India | Brand Name:N-TEX | Model Number:NA | Machine Type:Winding Machine |

| Product:Textile Yarn | Material Capabilities:Thread | Condition:New | Certification:ISO 9001:2008 |

| After-sales Service Provided:Engineers available to service machinery overseas | NA:NA | Cost efficient:Automatic Pirn Winder Machine | |

"2013 latest Pirn Winder Machine"

| Salient Features : -

| Compact and Sturdy construction. Elegant, economic, easy maintenance and trouble free operations. | | Rigid quality control. 24 hrs. working before dispatches. | | Strict supervision by highly qualified technical staff, backed by 30 years experience. |

Functions and Uses :

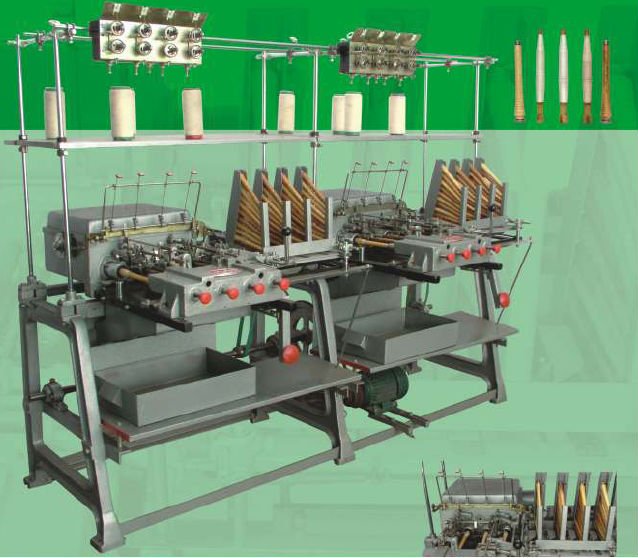

Being an automatic pirn winding machine, it is most ideal for winding synthetic polyethylene fiber yarn, cotton (10 counts to fine superfine) filament yarn, Silk, Nylon terry line, terry cot and woolen yarn.

Operations :

| Empty pirn (bobbins) used for winding are arranged in an adjustable magazine, according to pirn size. | | When the dimensions of pirn are adjusted the rotating pirn is held between the back and front carriers and, is also adjusted by moving the slipper box. | | The desired pirn diameter can be adjusted by regular wheel, mounted on left of spindle box. The cones are placed on platform above the machine. The yarn is unwounded from the cones passing through tension device, stops motion eyes and yarn guides and winds the pirn. | | Being and automatic machine it is automatically operated for pirn changing when the required length of yarn has been wound on the pirn. The wounded pirn is replaced by the empty one. Simultaneously, the weft is caught again and cuts in time. Moreover the machine stops automatically in case of breakage of yarn without loss of time. |

Technical Data :

The basic unit consists of spindles. It can be jointed together to obtain 8 spindles. Each unit of 4 spindles and 8 spindles driven individually. Each unit of 4 spindles driven individually by ½ HP electrical motor connected to a counter shaft mounted underneath the spindle box. 8 spindle units are driven by the gears mounted in spindle box. Oil circulating device is provided for continuous and thoroughly lubricating specially developed fiber gears for smooth and long life. Other parts are made from highly graded materials to obtain higher efficiency and zero maintenance.

Capacities of Pirn Winding Machine

| Minimum | Maximum | | Pirn Length | 150 mm | 190 mm | | Standard | 190 mm | 225 mm | | Second Type | 225 mm | 250 mm | | Third Type | | | | Bunch Length | 2 meters | 15 meters | | Spindle Speed | | | | For Cotton | 3000 RPM | 7000 RPM | | For Silk | 3000 RPM | 6000 RPM | | No. of Traverses per lift | 6-10 | 13 | Electric Motor

(recommended for Cotton & Silk yarn) | | | | For 4 Spindle Unit | 1/2 HP, 3 Phase A.C. | 1500 RPM | | For 8 Spindle Unit | 1 HP, 3 Phase A.C. | 1500 RPM |

Note :The above specifications are subject to change without any prior notice. |

|

| Packaging Detail:Wooden Full Case Packing OR Pallet Packing |

| Delivery Detail:6 to 8 weeks 2013 latest best Pirn Winder Machine |

Related Product for 2013 latest best Pirn Winder Machine