2012 newest professional and reasonable price industrial ceramic multi-cyclone dust collector

| Type:Fabric Dust Collector | Efficiency:14-240mt/h | Place of Origin:Henan China (Mainland) | Brand Name:Hongji |

| Model Number:X LG series | wind capacity (m³/h):1500-21600 | wind filtration speed(m/min):1-4 | running resistance:≤1200Pa |

| air consumption(m³/min):1.5-7.5 | blower power:2.2-11kw | under pressure:5000Pa | pressure(Mpa):0.4-0.6 |

| installation:we supply | certificate:ISO9001:2008 | guarantee:1 year |

General Introduction of Ceramic multi-cyclone Dust Collector:

Ceramic multicyclone Dust Collector is made of ceramic materials. It is widely used and has the characteristics of high resistance to corrosion, abrasion and temperature , with long service life and steady operation performance.

Characteristics of Ceramic multicyclone Dust Collector:

1.The ceramic movement is durable to deal with large volume of wind and with good adaptability.

2.Low investment at one time. Compared with the electrostatic dust collector, it has low investment, and do not need any circulating water while by comparision with water film dust collector.

3.It is convenient and easy to do the management, installation and maintenance work for Ceramic multicyclone Dust Collector.

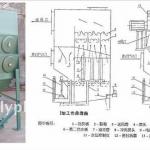

Operating principle:

When the dustladen gas enters into the dust chamber from the dust collector, dust separates with the gas on the effect of centrifugal after the rotation in the cyclone through guider. Then dust drops into the dust hopper and is exhausted through the airlock feeder. Now, the dust over 4μm has been removed. Purification gas should be into the desulfurization and sprayed by the water film with the liquid medicine. After chemical reaction, remaining dust and sulfur dioxide should be removed by handoperated valve. Following is dehydration procedure, firstly, desulfuration gas of reaction enters S channel. Secondly, via isolation of impingement and purification of steam-water separator, it is eliminated.

Technical parameter of Ceramic multicyclone Dust Collector:

Model | Suited boiler | Flue gas treatment (M3/h) | Collection efficiency % | Resistance of smoke /Pa | Ringelman emittance/grade | Desulfurization efficiency % | |||||||

| MW | t/h | ||||||||||||

| XLG-2 | 1.4 | 2 | 6000 | 98 | 1200-1500 | <1 | 70-80 | ||||||

| XLG-4 | 2.8 | 4 | 12000 | 98 | 1200-1500 | <1 | 70-80 | ||||||

| XLG-6 | 4.2 | 6 | 18000 | 98 | 1200-1500 | <1 | 70-80 | ||||||

| XLG-8 | 5.6 | 8 | 24000 | 98 | 1200-1500 | <1 | 70-80 | ||||||

| XLG-10 | 7.0 | 10 | 30000 | 98 | 1200-1500 | <1 | 70-80 | ||||||

| XLG-15 | 10.5 | 15 | 45000 | 98 | 1200-1500 | <1 | 70-80 | ||||||

| XLG-20 | 14 | 20 | 60000 | 98 | 1200-1500 | <1 | 70-80 | ||||||

| XLG-35 | 24.5 | 35 | 105000 | 98 | 1200-1500 | <1 | 70-80 | ||||||

| XLG-75 | 52.5 | 75 | 225000 | 98 | 1200-1500 | <1 | 70-80 | ||||||

| Packaging Detail:export standard ,nude packing in container or meet customer requirement. |

| Delivery Detail:15 days after confirming the orders |