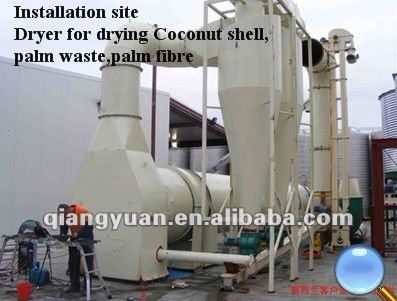

2012 Newest Model Coconut shell Drying Plants best selling in Malaysia 86-15137308741

| Type:Vacuum Drying Equipment | Place of Origin:Henan China (Mainland) | Brand Name:qiangyuan | Model Number:varies |

| color:up to the customer |

Coconut shell Drying Plant

1.Reasonable design

2.High efficiency

3.Low energy consumption

4.Easy to maintain

Application Scope

which is widely used in straw press briquettes fuel, charcoal machinery, wood chip granule fuel, sawdust press blocks, farming and animal husbandry engineering industry. Such as corn straw drying, soybean straw drying, cotton straw drying, wheat straw drying, sorghum straw drying, wood chips drying, wood shaving drying, sawdust drying, ginkgo leaf drying, mulberry leaves drying and drying the agricultural cellulosic-based materials.etc.

Analysis of drying characteristics

Itself drying characteristics can be classified into four segments. (The cooling segments whether required according to the next working procedure of product to determine)

AB section:preheating section

Material into dry machine by the feeder, in the action of high temperature hot air to make palm waste to warm up, and to the wet bulb temperature of the hot gas, now material water almost did not change, the hot air temperature has slightly lower, the heat quantity of its release is mainly used for palm waste preheated.

BC section:constant speed drying section

The drying rate is constant figure in this period, material surface always there surface moisture, heat of hot air transfer to material all used for evaporating. So material surface temperature all along keep the wet bulb temperature and unchanged, hot air temperature and palm waste water falling rapidly.

CD section: drying into the slow down section

Diffusion rate of palm fibre dwater inside less than the vaporizing rate of surface water, the surface of material do not have enough water, so the drying rate slow down. The heat of air transfer to the material more than the quantity of heat of water vaporization consumption, so material surface temperature rise ceaselessly, the air temperature further reduce.

DE section: cooling section

Material moisture content has fallen to request from value, material expel from drying machine, and then into the cooling system, make the dried palm waste temperature reduced quickly, avoid material to absorb moisture from the air again. The products which after cooling can be directly press block molding.

Some of ours other drying equipments as follows for many materials, please contact me for further negotiation

| Packaging Detail:up to the customer |

| Delivery Detail:30 working days after receiving the prepayment. |