2012 heavy mineral ore separation spiral separator recovery chute

| Condition:New | Type:Sprial Separator | Production Capacity:100 | Place of Origin:Jiangxi China (Mainland) |

| Brand Name:HengCheng | Model Number:spiral chute | Dimension(L*W*H):1560*1560*5230mm | Certification:ISO9001,ISO9001-2000 |

| Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas | Color:As your requested | Guaranteen:1 year |

| Sale service:For whole using life | Material of spiral part:Glass fibre reinforced plastic | Usage:Mineral separation | Capacity:0.15-8Tons/Hour |

| Power:1.1 kw | Feeding density:25-55% | Feeding size:0.3-0.02mm |

Detailed list of mineral grade

Extracting gold in one-off ,recovery rate attainability under 98%

| mineral | Grade |

| Tin | Above 50% |

| Tungsten | Above 50% |

| Titanium | Between 37%-40% |

| Iron | Between 58%-67% |

| Copper | Above 20% |

| sulphur | Above 30% |

| lead | Above 53% |

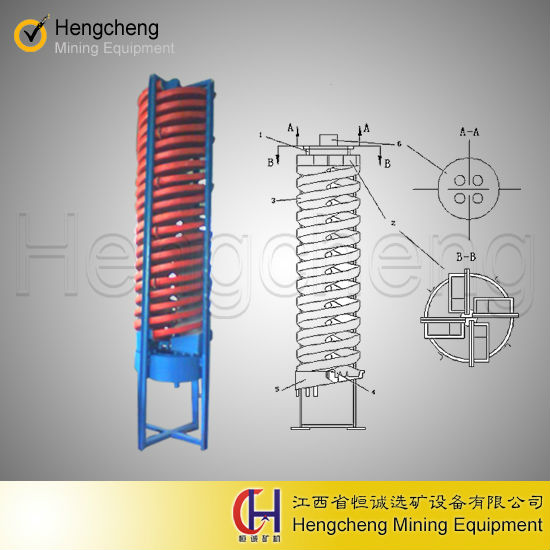

2012 heavy mineral ore separation spiral separator recovery chute

Spirals are gravity concentrators and separate minerals of different specific gravity according to their relative movement in response to gravity,centrifugal force and other forces in the fluid medium.It has extremely good performance and effects in processing placer of beach, riverside, seashore and stream.

Our Spirals are made of polyurethane lined fiber glass with wearable corundum inner surface.

Generally there are 5 turns in one start, single, twin, triple and quad starts available per column to suit capacity requirements.

Application

Rutile, ilmenite and zircon concentration

Iron ore, chromite and manganese beneficiation

Tin, tantalum and ore concentration

Gold, native copper and base metal recovery

Silica sands processing

Titano-magnetite concentration

Feature & Benefits

Reasonable structure and small occupation area

High recovery, high efficiency, and precise separation,

Light in weight, rust and corrosion resistant;

Simple installation and Minimal maintenance requirements

Low operating cost and long operating life

Reliable running with minimal operator attention

Strong adaptability to fluctuation of feeding amount, density, size and grade;

Technical Specification

Model | 5LL-1500 | 5LL-1200 | 5LL-900 | 5LL-600 | 5LL-400 | |

Outside dia(mm) | 1500 | 1200 | 900 | 600 | 400 | |

pitch(mm) | 540,720 | 900,720,540 | 675,540,405 | 450,360,270 | 240,180 | |

Pitch Dia Ratio | 0.75,0.6,0.45 | 0.75,0.6,0.45 | 0.75,0.6,0.45 | 0.75,0.6,0.45 | 0.6,0.45 | |

Lateral slope | 9° | 9° | 9° | 9° | 9° | |

Maximum starts per column | 4-2 | 4-2 | 4-2 | 3 | 2 | |

Feeding Size(mm) | 0.3-0.02 | 0.3-0.03 | 0.3-0.03 | 0.2-0.02 | 0.2-0.02 | |

Feeding Density(%) | 25-55 | 25-55 | 25-55 | 25-55 | 25-55 | |

Capacity(T/H) | 8-6 | 4-6 | 2-3 | 0.8-1.2 | 0.15-0.2 | |

External Size | Length(mm) | 1560 | 1360 | 1060 | 700 | 460 |

| Width(mm) | 1560 | 1360 | 1060 | 700 | 460 | |

| Height(mm) | 5230 | 5230 | 4000 | 2600 | 1500 | |

Weight (Kg) | 800 | 600 | 400 | 150 | 50 | |

To more know about 2012 heavy mineral ore separation spiral separator recovery chute ,kindly visit our website www.oreshaker.net

| Packaging Detail:export standard |

| Delivery Detail:Within 30 working days |